Scientists optimize productivity of pultrusion manufacturing process

A group of scientists from the Skoltech Center for Design, Manufacturing and Materials (CDMM) and University of Salerno (Italy) focused on improving pultrusion process productivity by optimizing pulling speed and structural parameters. They discovered and analyzed the interconnection between pulling speed of pultrusion and severity of manufactured induced shape distortions, matrix cracking and delaminations, mechanical characteristics. The research results are recently published in the journal Composite Structures.

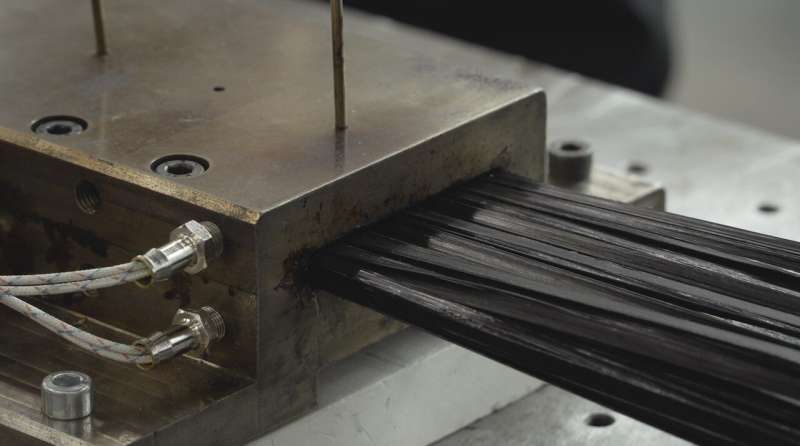

In recent years, fiber reinforced polymers (FRPs) have garnered considerable interest from the engineering community, resulting in the widespread adoption of composite structures. Among the many current composite manufacturing processes, pultrusion is the most efficient, combining high production rates with low material waste.

It is well known that the construction market is highly competitive. Therefore, every manufacturer is seeking for the possibility to increase productivity while still maintaining optimum structural characteristics of the produced elements.

Pultrusion process optimization involves careful consideration of the many parameters influencing the quality of the final product. One of the parameters to be considered is the pulling speed. Maximizing the pulling speed while preserving the quality of the produced profiles is necessary to increase efficiency and, thus, the pultrusion process's profitability.

The research team has found optimal pulling speed and identified its influence on structural parameters of the produced profiles. In particular, mechanical properties, delaminations and cracking behavior, and manufacturing induced shape distortions were analyzed.

The obtained outcomes open doors not only to the improvement of the manufacturing process but also to the development of a mathematical model able to predict linear elastic and viscoelastic behavior of profiles both at manufacturing and storage stages.

"The research results are of great importance since previous studies were analyzing structural parameters separately from each other. Thus, their interrelations were not accounted for when discussing the pulling speed's influence on structural characteristics of the pultruded profiles fabricated at different pulling speeds. The current study successfully filled this gap," said the first author of the study, Skoltech Ph.D. student Aleksander Vedernikov.

More information: Alexander Vedernikov et al. Effects of pulling speed on structural performance of L-shaped pultruded profiles, Composite Structures (2020). DOI: 10.1016/j.compstruct.2020.112967

Provided by Skolkovo Institute of Science and Technology