Insights on service life of industrial components

It is of technological importance to understand the accumulation of plastic damage or deformation in components under various operating conditions in order to estimate their service lifetime.

A team of international researchers led by ANSTO have compared two novel techniques that can be used to assess the degree of accumulated plastic damage in alloys by measuring the amount of dislocations present in the microstructure.

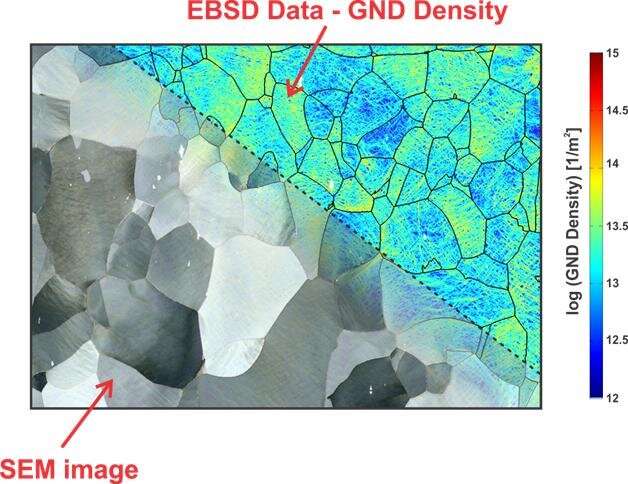

Lead author Dr. Ondrej Muránsky said they used Electron Back-Scatter Diffraction (EBSD) and High-Resolution Synchrotron Diffraction (HRSD) to obtain complementary information about the dislocations stored by the material as a result of applied stress.

In the study published in Acta Materialia, Muránsky and his collaborators from Queen's University (Canada), University of California (U.S.), and Argonne National Laboratory (U.S.) compared EBSD and HRSD techniques, and developed Matlab code, which allows the theoretical estimation of plastic damage at the macroscopic level from ESBD data.

A reviewer for Acta Materialia commented, "Firstly, it [the paper] is very well written and quite easy to follow. The authors have made a great attempt to really explaining well to the reader the two different methodologies. Secondly, the authors are very honest in their assessments and do not try to hide the shortcomings of either technique."

The study evaluated the advantages and shortcomings of the two techniques by analyzing the same samples using both methods. The authors used Ni201, which is a model microstructure of high-temperature, radiation and molten salt corrosion-resistant alloys for use in future energy generation and energy storage systems.

It was found that the EBSD technique was more sensitive to a small amount of plastic damage (minimum detectable amount of dislocations is 2E12 m-2), while the HRSD technique is more accurate when measuring higher amount of plastic damage (minimum detectable amount of dislocations is 1E13 m-2).

"Such behavior highlights the complementarity of EBSD and HRSD when attempting to quantify dislocations (plastic damage) in a material that has experienced an unknown amount of accumulated plastic damage during service ," said Muránsky.

The researchers were able to derive a mathematical relationship between geometrically-necessary dislocations (GNDs) measured using EBSD and the size of coherently scattered domains (CSDs) measured using HRSD.

"This work would have not been possible without exceptional work of Tim Palmer who carefully prepared samples for both EBSD and HRSD measurements," said Muránsky.

The ESBD was undertaken at ANSTO's microscopy facility. The HRSD measurements were done at the Advanced Photon Source at Argonne National Laboratory in the US.

HRSD will be available at ANSTO when a new Advanced Diffraction and Scattering beamline is built at the Australian Synchrotron, as part of the Bright project.

More information: O. Muránsky et al. On the measurement of dislocations and dislocation substructures using EBSD and HRSD techniques, Acta Materialia (2019). DOI: 10.1016/j.actamat.2019.05.036

A presentation about the research is also available. www.ansto.gov.au/sites/default … les/2019-08/Muransky%20Acta%20Mater.%20Dislocations.pdf