Novel digitization methods and restoration technologies for preserving cultural heritage

How can we protect and preserve cultural heritage? Researchers from 16 Fraunhofer Institutes are collaborating on the executive board's cultural heritage project to develop the technologies needed for this undertaking.

Whether it is visible in historical temples, ancient statues, or paintings by the great masters, cultural heritage must be preserved. But maintaining historical art treasures is not solely the responsibility of restorers – this task calls for research and the high-tech solutions it can provide. A glance inside some of the Fraunhofer labs reveals numerous researchers working on just these kinds of solutions.

A total of 16 Fraunhofer Institutes are collaborating on the cultural heritage research project, together with their partners, the Dresden State Art Collections and the Saxon State and University Library Dresden (SLUB). The Fraunhofer executive board is supporting the project with €1.5 million in funding. "That makes it one of the largest German research projects in the field of cultural heritage," says Dr. Johanna Leissner, the Brussels-based coordinator of the executive board project and spokeswoman for the Research Alliance Cultural Heritage. The project results were presented this past September at the closing event in Dresden – as a contribution by the Fraunhofer-Gesellschaft to the European Year of Cultural Heritage.

3-D digitization on a conveyor belt

One way to save our cultural heritage for posterity is to digitize works of art in 3-D, so that they can be used at any time, even in parallel: while research teams are examining a digitized temple online, museum visitors all over the world can simultaneously take a virtual stroll through the ancient building.

Until now, this 3-D digitization was a time-consuming undertaking. "Now, for the first time, our CultLab3D automated scanning facility makes it possible to transfer entire museum collections to the digital world," explains Pedro Santos, department head at the Fraunhofer Institute for Computer Graphics Research IGD in Darmstadt. Simply scan an object's QR code and lay the piece on a tray – the rest happens automatically. The result is a three-dimensional digital replica, and it is produced at quite a high speed: a new artifact can be digitized every five minutes. Nine cameras photograph the object from multiple sides.

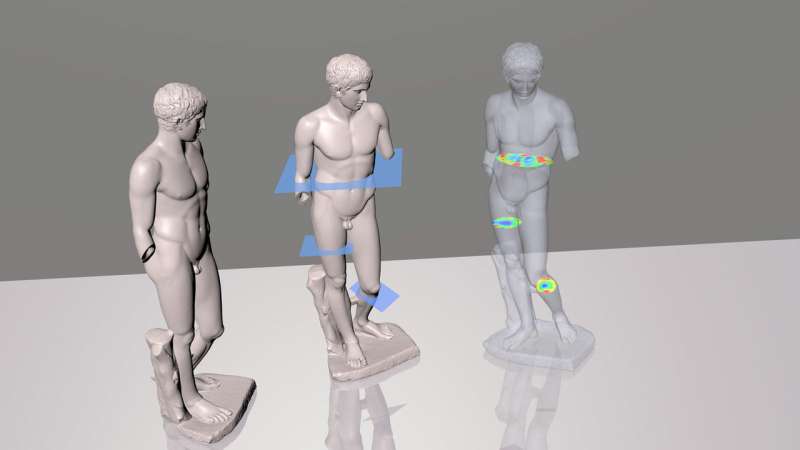

Special software processes these images to generate the three-dimensional digital replica. This method also works with large statues, although it must then be performed manually rather than automatically. This is how the Fraunhofer IGD researchers digitized the Pergamon Altar – using a lightweight laser scanner. Now the research teams are taking it one step further: "In the future, we will not only depict the geometry, texture and optical material properties – in short, an object's exterior – but will also include its interior," says Constanze Fuhrmann, scientist and coordinator of the subproject "Sculptures: Novel damage and material analysis in 3-D" at Fraunhofer IGD. "The data on an object's interior and exterior, obtained using various technologies, will be uniformly combined to form a 3-D model that is then visualized in 3-D in space in front of the monitor." This first-time combination of digital Fraunhofer methods enables completely new damage and material analyses in 3-D (see box "3-D digital analysis of material and damage").

3-D digitization meets ultrasound

For instance, the experts expanded the CultLab3D approach to include an ultrasound analysis. "In other words, in the digital representation, the restorers can zoom in to the object's interior, enabling them to see immediately whether there are any hidden instabilities, corrosion or holes," says Peter-Karl Weber, a group manager at the Fraunhofer Institute for Biomedical Engineering IBMT. What's more, these analyses can now be completed in just a few seconds.

This is made possible by an elastic belt fastened to the object. "An ultrasonic transducer is attached to each belt. Special electronics enable these transducers to switch between transmitter and receiver. Now, instead of having to constantly reposition the ultrasonic transducer, one needs only place the belt on the work of art. Thanks to QR codes on the transducers, a camera can identify the position at which the ultrasound tomogram was recorded, and software inserts the ultrasound images into the digital scan.

For ultrasound examinations, doctors apply a gel to patients' skin to transmit the ultrasonic waves into the body, but this gel would damage works of art. Researchers at the Fraunhofer Institute for Applied Polymer Research IAP are therefore developing a material that enables dry-coupled ultrasonic testing. This material has the same properties as the gel and can be removed without leaving any residue.

Enameled gold in the Green Vault

The Green Vault in the Dresden Castle is one of the most famous museums in Saxony. It also houses court jeweler Dinglinger's filigree enameled gold treasures depicting the court of India's Great Mogul.

For decades, the pieces were exhibited in showcases that, unbeknownst to the museum, were off-gassing many harmful substances. As a result, the intricate en-ameling gradually began to peel off. The fragments were meticulously collected, but how would restorers be able to reattach them? Any suitable conservation material must meet some extremely strict requirements: it has to be transparent, highly durable and have similar properties as glass, and it must also firmly bond enamel and metal.

"We developed a suitable material for this at the Fraunhofer Institute for Silicate Research ISC in Würzburg twenty years ago: enamel ORMOCER ," explains Dr. Gerhard Schottner, who heads the department for glass research there. Besides its suitability for lasting conservation of enameled treasures, it can also permanently bond ivory and rock crystal, as was discovered in the restoration laboratory at the Dresden State Art Collections. Unfortunately, over the years, the raw materials supplied by industry sources became unavailable in the required quality, and even the slightest impurities can lead to differences in the synthesis of these silicon-organic compounds. So what now? "We need the best material for preserving cultural heritage, but the amounts required are fairly small," explains Schottner. This makes material development and sales unprofitable for business-oriented companies. The executive board project and funding from the German Federal Environmental Foundation offered a way out of this dilemma. The ISC team analyzed the raw materials and the individual steps in their production down to the last detail of the chemical reactions, including moisture and temperature levels, and examined the impact of the various solvents on the final product. Now the process is nearly complete: the material is in the final testing phase, and the restorer in charge, Rainer Richter from the Dresden State Art Collections, is extremely satisfied.

Provided by Fraunhofer-Gesellschaft