New technique uses templates to guide self-folding 3-D structures

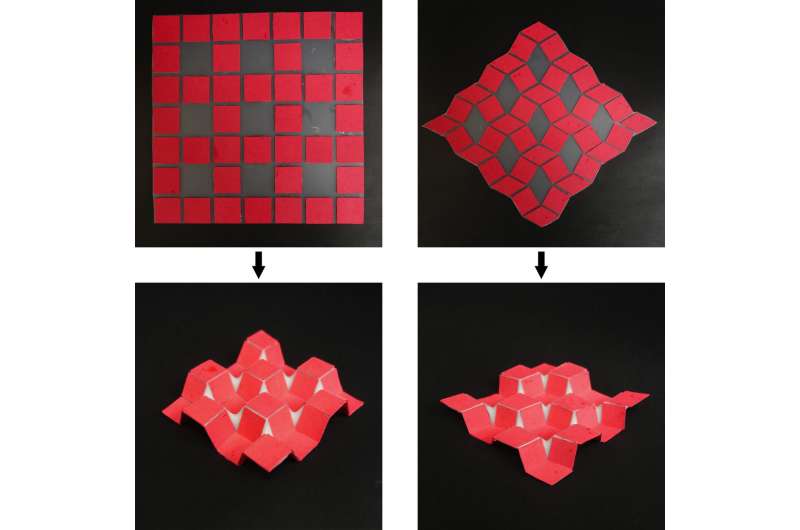

Researchers from North Carolina State University have developed a new technique to control self-folding three-dimensional (3-D) structures. Specifically, the researchers use templates to constrain deformation in certain selected areas on a two-dimensional structure, which in turn dictates the resulting 3-D structure of the material.

The new technique does not rely on cutting or printing on the material, as most other self-folding origami techniques do. It is also different from continuous shape morphing, which is typically controlled by engineering the in-plane strain at various parts of the material. Instead, the researchers applied paperboard sheets to a polymer substrate, forming specific patterns.

"When heat is applied to the polymer, it shrinks," says Yong Zhu, a professor of mechanical and aerospace engineering at NC State and corresponding author of a paper on the work. "However, the sections of polymer that are attached to the paperboard are restrained from shrinking, causing the overall substrate to bend and curve."

By varying the pattern made by the paperboard templates, the researchers are able to create a variety of shapes, from simple cones to complex, tiered structures. The self-folding operations can be executed at temperatures as low as 120 degrees Celsius.

"This is a proof of concept paper, and next steps include incorporating functional electronic elements into the material, giving it potential value for manufacturing applications," says Jianxun Cui, first author of the paper and a postdoctoral researcher at Carnegie Mellon University who worked on this project while a Ph.D. student at NC State.

The paper, "Origami/Kirigami Guided Morphing of Composite Sheets," is published in the journal Advanced Functional Materials.

More information: "Origami/Kirigami Guided Morphing of Composite Sheets," Advanced Functional Materials (2018). onlinelibrary.wiley.com/doi/fu … .1002/adfm.201802768

Journal information: Advanced Functional Materials

Provided by North Carolina State University