Research toward viable, safe batteries overcomes high resistance, low capacity solid-state barriers

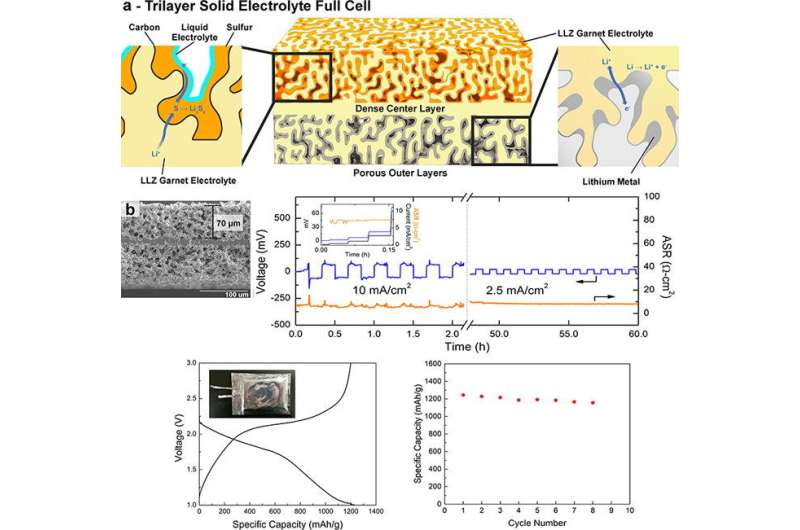

Engineers at the University of Maryland have developed a means to overcome obstacles in the development of solid-state batteries, primarily high resistance and low capacity. Dr. Eric Wachsman, Director of the Maryland Energy Innovation Institute and William L. Crentz Centennial Chair in Energy Research, and his group have broken these barriers through the fabrication of a uniquely microstructured solid electrolyte architecture based on a doped Li7La3Zr2O12 (LLZ) ceramic Li-conductor. The paper describing this technique was recently published in Materials Today.

Dr. Eric Wachsman, lead researcher, noted, "There has been tremendous interest in solid-state batteries due to their inherent safety and potential for game changing increase in energy density by use of Li metal anodes. However, until this work the Li-cycling current densities were too low to achieve commercially viable charge and discharge rates. Now that this has been achieved the potential of solid-state batteries can finally be realized."

Trilayer structures were produced through a low-cost, easily scalable tapecasting process. Without any gaps between grains, the dense layer is free from structural defects, blocking dendritic lithium growth that could short circuit the cell and increasing mechanical strength. The porous-dense-porous LLZ trilayer structure serves multiple functions, resulting in a low resistance, mechanically strong structure capable of high-rate lithium cycling.

Dr. Greg Hitz, CTO of Ion Storage Systems, a battery start up company out of UMD, also stated, "Our group's extensive experience as electrochemists and ceramists led to the trilayer design that we believe is the ideal configuration for next-generation solid state batteries. The demonstration of high rate lithium cycling in the trilayer ceramic structure was the realization of our multi-year vision and represents a platform for lithium-sulfur, layered oxide cathodes, high voltage spinels, or other future battery chemistries."

The technique has already surpassed DOE Fast-Charge current density goal with a large per-cycle areal capacity, which has never previously been demonstrated for lithium cycling in solid electrolytes. Future work will focus on increasing cumulative plating capacity and fraction of lithium passed per cycle to further achieve these targets. These results offer a commercially viable means of producing safe, non-combustible, lithium batteries with high specific energy and high specific density.

More information: Gregory T. Hitz et al. High-rate lithium cycling in a scalable trilayer Li-garnet-electrolyte architecture, Materials Today (2018). DOI: 10.1016/j.mattod.2018.04.004

Journal information: Materials Today

Provided by University of Maryland