New method of measuring internal stresses for aerospace and aircraft engineering

Composite materials have become integral to industry, used in aviation and space technologies, as well as auto manufacturing and mining. However, internal stress assessment with composite material designs has long been challenging. Scientists from the NUST MISIS Center of Composite Materials, led by Professor Sergey Kaloshkin, have now proposed a non-contact method of internal voltage control in polymer composites. The researchers report that it is now possible to more effectively assess the degree of internal damage during the operation of aircraft parts, oil pipelines, ship hulls, and other industrial and transport facilities.

Andrey Stepashkin, Candidate of Technical Sciences and Senior Research Associate at the NUST MISIS Center of Composite Materials, discussed why the problem of assessment is so critical: "There are composite materials in which the internal stress reaches 95 percent of the tensile strength after fabrication. It will crack if we add even a little more pressure. For example, a number of composite materials, processing excellent heat and thermal resistance and created for the Buran spacecraft, had a high level of internal stresses due to the characteristics of their manufacturing. This has become a huge problem. To get one functioning piece of black plating, 50 pieces had to be thrown out."

There is no such level of internal stress in carbon plastics, fiberglass, or hybrid composite materials after manufacturing. Instead, stresses arise and accumulate under the influence of operating loads, the external environment and weather, which can lead to damage in the material and reduce its load-bearing capacity. Such changes affect operational safety and must be identified in a timely manner.

There are methods to control stresses in composite structures, but they are often inconvenient, and sometimes are not acceptable due to forecast accuracy. For example, non-contact methods (ultrasonic, acoustic flaw detection, shearography) allow researchers to detect defects that have already occurred, and do not provide information about the stress within the material or about their distribution throughout the structure. The accepted methods for assessing the stress state in a framework all require contact and connection to the material using adhesive film sensors. That's why detecting something before a defect appears is currently impossible with non-contact methods.

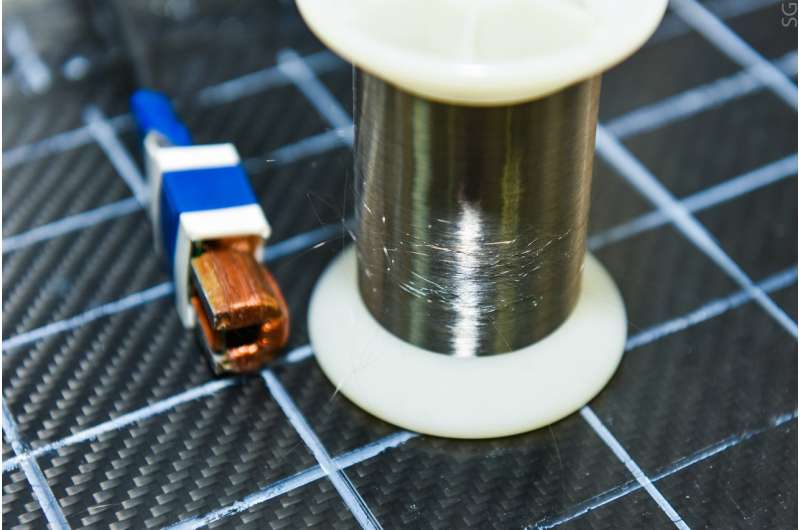

The idea of this research is to use amorphous soft magnetic circuits 10 to 60 microns in diameter to assess the stress state in composite materials. During the manufacturing stage, wires are laid between the carbon fiber layers, forming a stress-sensitive grid.

The stress state surrounding the micro-wire affects how the substance reacts to external magnetic fields. Accordingly, these measurements can be carried out without contact, a connection to the sensing element, or adhesive sensors—the detection system is embedded inside the material during the manufacturing stage. It is also important that researchers only have to use one sensor, unlike some methods of flaw detection that require exposing the equipment on both sides. This technology significantly simplifies, speeds up, and reduces the cost of assessing the state of composite materials by making repairs easier and allowing more accurate predictions about future defects, all in a contactless manner.

The researchers have worked out how to introduce soft magnetic wires into the composite material and how to make sure that the properties of the composite material from this do not deteriorate. Likewise, they have also mastered different measurement modes. Several representatives of the aviation and space industries, as well as developers of composite materials, have praised this new methodology. According to Andrey Stepashkin, researchers now want to develop a field prototype and measure systems based on lab devices.

"We have made the first step of a long journey. But we already see a practical application of our development. In addition, it has more features—the micro-wire mesh introduced into the material can provide an additional drain of the static charge that occurs in fiberglass structures. Our wires are quite capable of replacing metal grids which are now inserted into these materials," he added.

The research work is published in the Journal of Alloys and Compounds.

More information: M. Churyukanova et al, Non-contact method for stress monitoring based on stress dependence of magnetic properties of Fe-based microwires, Journal of Alloys and Compounds (2018). DOI: 10.1016/j.jallcom.2018.02.342

Provided by National University of Science and Technology MISIS