How to cool a smartphone

NUST MISIS scientists have developed composites that conduct heat many times better than their counterparts and are even subject to simple and cheap processing. By using the newly obtained technology in modern electronics, it is possible to solve the problem of PCB overheating. The research results were published in the Journal of Alloys and Compounds.

Electronics can overheat, freezing up, automatically restarting, etc., but this is only the visible part of the problem. With regular overheating, a device simply degrades as elevated temperatures are always dangerous for its inner components. Often, overheating is manifested by regular "freezes" after launching the gadget, or worse, by a blue screen or an unexpected shutdown. Computer and smartphone processors and video cards are the most sensitive to temperature rises, as high temperatures reduce the time of their stable operation. Although modern devices are automatically turned off when a critical temperature is reached, a more normal increase in temperature leads to processor errors and even the chip's breakdown.

To solve this problem, NUST MISIS scientists have proposed a universal method for producing cheap, light composites with high thermal conductivity and profound mechanical properties.

"A material that conducts heat well and doesn't conduct electric current and thus has a polymer base, is potentially cheaper than common analogues in the cycle of production and processing, so that has become our aim," said Dmitry Muratov, one of the study's authors, and senior researcher at the NUST MISIS Department for Functional Nanosystems and High-Temperature Materials.

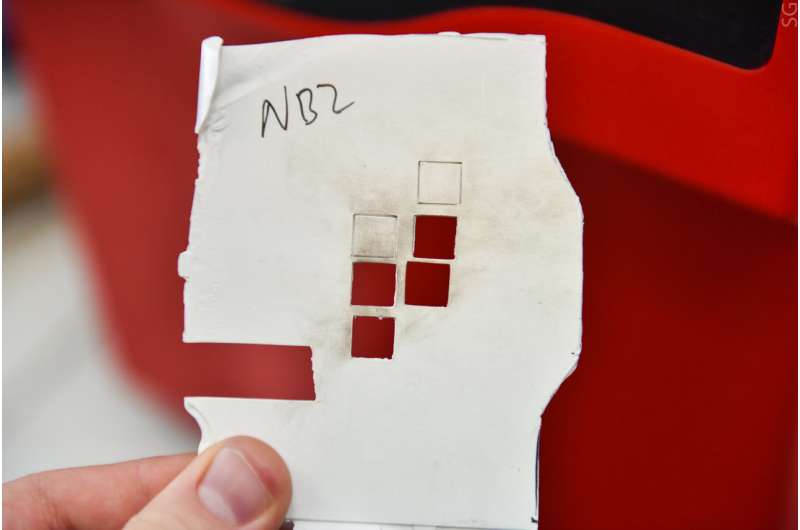

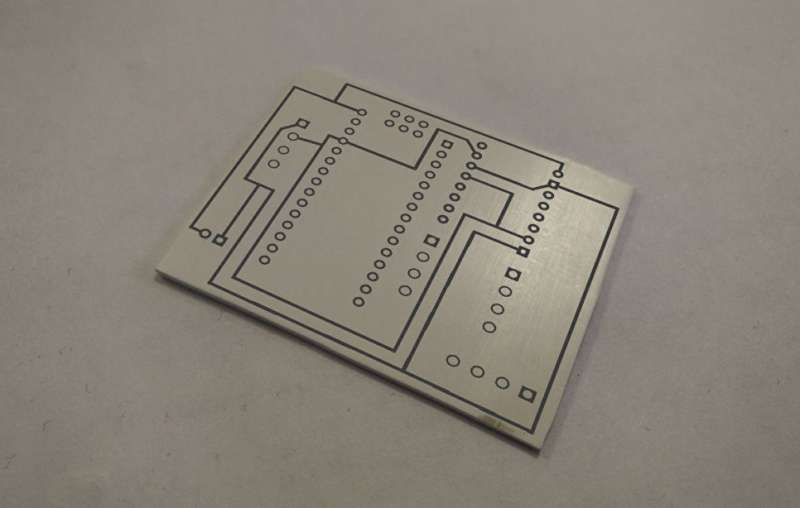

According to Muratov, the obtained composite is very promising for replacing reinforced layered materials in printed circuit boards or in small electronics' cases where there is noticeable heat generation (for example, diode lamps).

The technology implemented at NUST MISIS implies that high-density polyethylene is used as a polymer basis, and hexagonal boron nitride as a material filler. The research team has developed an optimal combination of processing modes to ensure the filler's desired properties.

"As a result, we have achieved positive results. The work demonstrates the strength of the composite based on polyethylene and boron nitride in the amount of 24 MPa, and its thermal conductivity has become at least two or three times higher than that of fiberglass, which is used in analogue devices," said Dmitry Muratov.

Muratov believes the material can effectively replace fiberglass in modern electronics because it doesn't have corresponding disadvantages of toxic epoxy resins in the composition. Besides the fact that the composite removes heat to the desired extent—about 1W/m*K—it is also easy to recycle.

"The economic benefit of our materials is due to the ease of utilization, while fiberglass is extremely difficult to process because its polymer is made of reactive plastics (epoxy resins) that cannot be reused after curing," said Muratov.

Currently, scientists are collaborating with the University of Nebraska-Lincoln (U.S.) in th synthesis of two-dimensional materials and studies of their properties. They are looking for a way to dramatically increase the thermal conductivity of composites by using materials where high rates have been theoretically justified.

More information: Dmitry S. Muratov et al, Controlling thermal conductivity of high density polyethylene filled with modified hexagonal boron nitride (hBN), Journal of Alloys and Compounds (2017). DOI: 10.1016/j.jallcom.2017.11.234

Provided by National University of Science and Technology MISIS