New insights into molecular-level processes could help prevent corrosion and improve catalytic conversion

Engineers have long known water vapor can accelerate corrosion of metals and alloys, but the exact mechanisms remain elusive and therefore difficult to prevent. Now an international research team has peered into the atomic-level workings of water vapor corrosion. Their work reveals how the involvement of protons speeds the corrosion process.

Understanding how water vapor such as mist or steam corrodes metals and alloys can help engineers keep industrial systems working at peak performance longer. Armed with that knowledge, engineers can also improve catalytic conversion processes and enhance ionic conduction in materials.

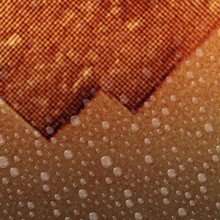

Scientists from EMSL, the Environmental Molecular Sciences Laboratory, an Office of Science user facility, collaborated with colleagues at Pacific Northwest National Laboratory, Chinese Academy of Sciences, and State University of New York at Binghamton to study the effect of water vapor and elevated temperatures on a nickel-chromium alloy. Using EMSL's environmental transmission electron microscope, they were able to directly observe oxide growth on a nickel-chromium alloy during corrosion at the atomic level. What they discovered was a complex dance of protons, cations, and anions that led to increased corrosion and a more porous structure of the oxide. They then modeled the process through computer simulations to confirm their findings.

Their work provides insights into how water vapor might change other materials, particularly at elevated temperatures.

More information: Langli Luo et al. Atomic origins of water-vapour-promoted alloy oxidation, Nature Materials (2018). DOI: 10.1038/s41563-018-0078-5

Journal information: Nature Materials

Provided by Environmental Molecular Sciences Laboratory