Polymers that mimic chameleon skin

Biological tissues have complex mechanical properties – soft-yet-strong, tough-yet-flexible – that are difficult to reproduce using synthetic materials. An international team has managed to produce a biocompatible synthetic material that replicates tissue mechanics and alters color when it changes shape, like chameleon skin. These results, to which researchers from CNRS, Université de Haute-Alsace and ESRF, the European Synchrotron, have contributed with colleagues in the US (University of North Carolina at Chapel Hill, University of Akron), are published on March 30, 2018 in Science. They promise new materials for biomedical devices.

To produce a medical implant, we need to select materials with similar mechanical properties to those in biological tissues, so as to mitigate inflammation or necrosis. A number of tissues including the skin, the intestinal wall, and heart muscle, have the characteristic of being soft yet stiffening when they are stretched. Until now, it has been impossible to reproduce this behavior with synthetic materials.

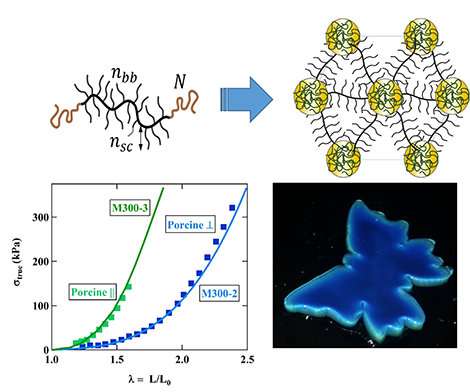

The researchers have attempted to achieve this with a unique triblock copolymer. They have synthesized a physically cross-linked elastomer composed of a central block onto which side chains are grafted (like a bottle brush) and with linear terminal blocks at each end (See figure). The researchers have found that by carefully selecting the polymer's structural parameters, the material followed the same strain curve as a biological tissue, in this case pig skin. It is also biocompatible, since it does not require additives, e.g. solvent, and remains stable in the presence of biological fluids.

Another property of the material appeared during the experiments—it changes color upon deformation. As the scientists have shown, this is a purely physical phenomenon caused by light scattering from the polymer structure. Atomic force microscopy and X-ray diffraction experiments have shown that the terminal blocks of these polymers assemble in nanometer spheres distributed in a brush-polymer matrix. Light interferes with this microphase-separated structure to produce color according to the distance between the spheres; so when the material is stretched, it changes color. It is the same mechanism that explains how chameleons change color.

The researchers have therefore succeeded in encoding in a unique synthetic polymer with both mechanical properties (flexibility, strain profile) and optical properties. This has never previously been achieved. By adjusting the length or density of the brush's various side chains, these properties can be modulated. This discovery could lead to medical implants or more personalized prostheses (vascular implants, intraocular implants, replacement of intervertebral discs), and also to materials with completely new strain profiles, and applications that have not yet been imagined.

More information: Chameleon-like elastomers with molecularly encoded strain-adaptive stiffening and coloration. M. Vatankhah-Varnosfaderani, A.N. Keith, Y. Cong, H. Liang, M. Rosenthal, M. Sztucki, C. Clair, S. Magonov, D.A. Ivanov, A.V. Dobrynin, S.S. Sheiko. Science, 30 March 2018. DOI: 10.1126/science.aar5308

Journal information: Science

Provided by CNRS