Physicists speed up droplet-wrapping process

Experimental physicists at the University of Massachusetts Amherst today report that they have developed a fast, dynamic new process for wrapping liquid droplets in ultrathin polymer sheets, so what once was a painstaking process taking tens of minutes can now be done in a fraction of a second.

Physics professor Narayanan Menon, with current postdoctoral researcher Deepak Kumar, former postdoc Joseph Paulsen and professor of polymer science Thomas Russell, report their findings in the current issue of Science. Paulsen is now at Syracuse University.

As Menon explains, many research groups around the world are working on the problem of wrapping liquid droplets to stabilize emulsions, which can be useful in drug delivery systems, for example, or for remediating oil spills.

The customary method is to use a layer of fluid that acts as a surfactant to keep oils and water in suspension. Mayonnaise is an emulsion of oil and water, Menon notes, with egg white as the surfactant that holds it in suspension. But a liquid surfactant layer has no rigidity, it cannot hold a shape. The UMass Amherst researchers were looking for a wrap with a finite rigidity.

He says, "Let's say I ask you to wrap up a basketball and I give you tape and paper. You do the best you can, but it's not going to come out very neatly. It will have gaps and overlaps. With our new process, you throw the basketball at the paper, and it comes out perfectly wrapped."

Menon adds, "If you're thinking of doing this sort of wrapping over and over, speed and ease of use make all the difference. The quick and simple solution Kumar has found is a huge advance, and once he mastered it and identified the most important parameters, he found he could get adventurous and make different shapes. We show that we have made cubes and a tetrahedron, for example."

Also, "The materials are common polymers and common liquids, just oil and water. No magic ingredients needed, and we can go freely from oil droplets in water and vice versa. The seams are held in place by the dislike of the fluid inside for the fluid outside, so the wrapping edges meet right at the seam and there is no overlap and no gap."

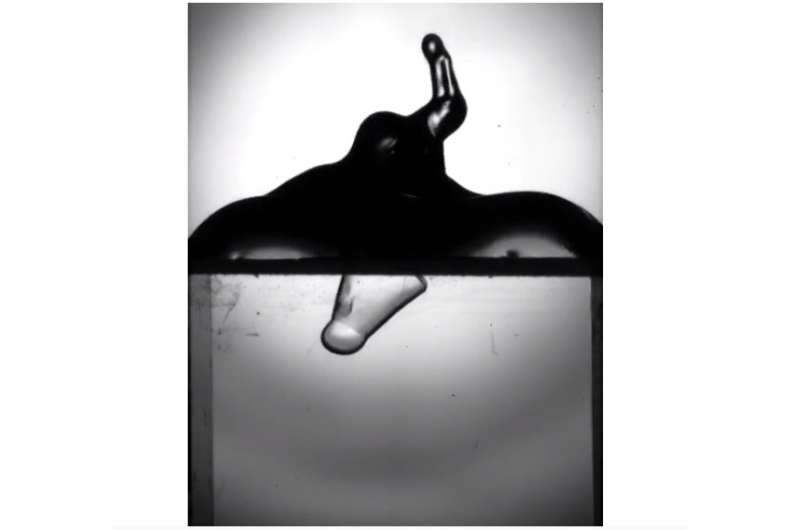

Kumar, first author of the paper, points out that the new technique exploits the fast dynamics of droplet impact to achieve wrapping of oil droplets by ultrathin polymer films in a water phase. "Despite the violence of splashing events, the process robustly yields wrappings that are optimally shaped to maximize the enclosed fluid volume and have near-perfect seams," he and colleagues write. "We achieve wrappings of targeted three-dimensional shapes by tailoring the two-dimensional boundary of the films and show the generality of the technique by producing both oil-in-water and water-in-oil wrappings."

Important factors involved in the practical success of the new method, Kumar notes, are droplet fluid density and the size of the droplet in relation to the size of the thin polymer sheet. Menon quips, "It doesn't work if you throw a basketball at a bed sheet, nor at a postage stamp. The size of the droplet and the sheet must be related."

An unexpected bonus of this work, the authors point out, is that they have achieved not only the practical success, but they were able to answer part of the deeper scientific question of mechanism. Kumar says, "We propose some ideas, but we don't have the answer to all the questions."

Menon says he hopes experimental physicists who read about this work will quickly grasp that "it's technically easy and you should go do it for yourself. In fact, you should take it and go in directions that we haven't thought about. We hope other researchers will think of more and different applications than we would by ourselves. If you want to add complexity, you could put a layer or a pattern on the inside of the wrapping, or you could add a window to make it slightly leaky. Once you know how to do the technique, it's not fussy."

More information: D. Kumar el al., "Wrapping with a splash: High-speed encapsulation with ultrathin sheets," Science (2018). science.sciencemag.org/cgi/doi … 1126/science.aao1290

Journal information: Science

Provided by University of Massachusetts Amherst