On the rebound

Our bodies have a remarkable ability to heal from broken ankles or dislocated wrists. Now, a new study has shown that some nanoparticles can also "self-heal" after experiencing intense strain, once that strain is removed.

New research from the U.S. Department of Energy's (DOE) Argonne National Laboratory and Stanford University has found that palladium nanoparticles can repair atomic dislocations in their crystal structure. This newly discovered twist could ultimately advance the quest to introduce self-healing behaviors in other materials.

"It turns out that these nanoparticles function much more like the human body healing from an injury than like a broken machine that can't fix itself." - Andrew Ulvestad, Argonne materials scientist.

The research follows a study from last year, in which Argonne researchers looked at the sponge-like way that palladium nanoparticles absorb hydrogen.

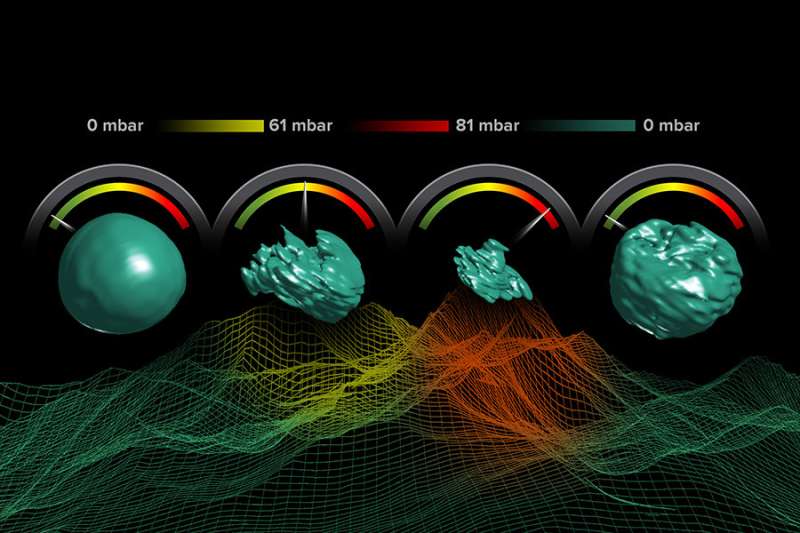

When palladium particles absorb hydrogen, their spongy surfaces swell. However, the interiors of the palladium particles remain less flexible. As the process continues, something eventually cracks in a particle's crystal structure, dislocating one or more atoms.

"One would never expect the dislocation to come out under normal conditions," said Argonne materials scientist Andrew Ulvestad, the lead author of the study. "But it turns out that these nanoparticles function much more like the human body healing from an injury than like a broken machine that can't fix itself."

Ulvestad explained that the dislocations form as a way for the material to relieve the stress placed on its atoms by the infusion of additional hydrogen. When scientists remove the hydrogen from the nanoparticle, the dislocations have room to mend.

Using the X-rays provided by Argonne's Advanced Photon Source, a DOE Office of Science User Facility, Ulvestad was able to track the motion of the dislocations before and after the healing process. To do so, he used a technique called Bragg coherent diffraction imaging, which identifies a dislocation by the ripple effects it produces in the rest of the particle's crystal lattice.

In some particles, the stress of the hydrogen absorption introduced multiple dislocations. But even particles that dislocated in multiple places could heal to the point where they were almost pristine.

"In some cases, we saw five to eight original dislocations, and some of those were deep in the particle," Ulvestad said. "After the particle healed, there would be maybe one or two close to the surface."

Although Ulvestad said that researchers are still unsure exactly how the material heals, it likely involves the relationship between the material's surface and its interior, he explained.

By better understanding how the material heals, Ulvestad and his colleagues hope to tailor the dislocations to improve material properties. "Dislocations aren't necessarily bad, but we want to control how they form and how they can be removed," he said.

The study, entitled "The self-healing of defects induced by the hydriding phase transformation in palladium nanoparticles," appeared November 9 in Nature Communications.

More information: A. Ulvestad et al, The self-healing of defects induced by the hydriding phase transformation in palladium nanoparticles, Nature Communications (2017). DOI: 10.1038/s41467-017-01548-7

Journal information: Nature Communications

Provided by Argonne National Laboratory