Panasonic develops unique vacuum insulated glass based on its plasma display panel technology

Panasonic Corporation today announced it has developed and succeeded in mass production of thin, high-performance vacuum insulated glass by applying technologies the company accumulated in the development and manufacturing of plasma display panels (PDPs). The glass achieves a heat transfer coefficient (Ug value) of 0.7 (W/m²K), the industry's top-class insulation performance for glass with a total thickness of 6 mm, which is equal to or greater than triple glass containing argon gas with a total thickness of about 3 cm.

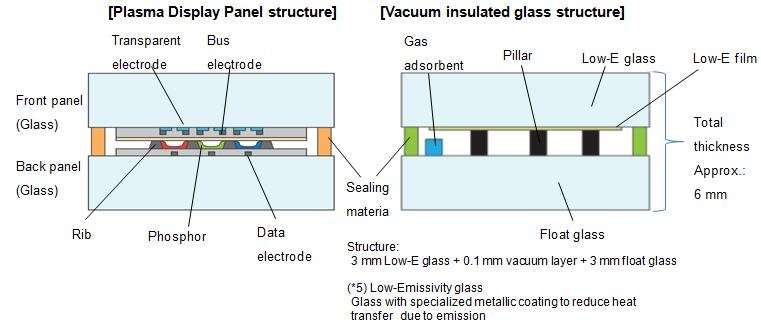

A PDP displays an image by causing phosphors to emit light within an extremely thin vacuum layer between two sheets of glass that are vacuum-sealed. Generally, to maintain the vacuum state within the glass, vacuum sealing material technology is required to suppress emission of gas from the substances inside the vacuum layer while maintaining a high vacuum state. Panasonic has retained the vacuum glass panel manufacturing technology and lead-free vacuum maintaining material technology that it cultivated during the development and manufacture of PDPs.

Now, Panasonic has realized a practical vacuum insulated glass with excellent insulation performance by developing a new slim-model gas adsorbent that adsorbs the gas that occurs within the vacuum layer, and a new low thermal conductive component that forms a 0.1 mm gap between the two sheets of glass. Due to the unique manufacturing method the company developed, the exhaust hole sealing component required to form the vacuum space is not present on glass surface, which gives a smooth, flat product appearance. Furthermore, this product uses no lead, a hazardous substance, ensuring safety and environmental friendliness.

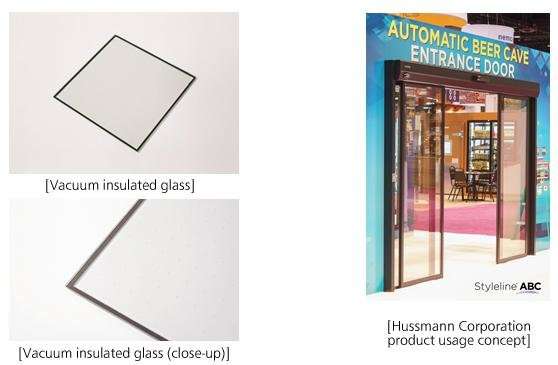

This new vacuum insulated glass will be first used by Hussmann Corporation, the U.S. refrigerator and freezer showcase manufacturer wholly-owned by Panasonic, prior to commercialization. Hussmann will use the glass for automatic glass door systems for walk-in coolers and freezers in convenience stores and supermarkets to address tightened regulations by the United States Department of Energy.

Panasonic plans to offer the glass as part of its insulation solutions in Japan and overseas to respond to the global trend toward stricter emission regulations, as seen in the Paris Accord, and help achieve a sustainable society.

Features

1. Industry's top-class insulation performance for anneal glass with a total thickness of approximately 6 mm (heat transfer coefficient U value = 0.7 (W/m²•K))

A PDP displays an image by causing phosphors to emit light within an extremely thin vacuum layer between two sheets of glass that are vacuum-sealed. Panasonic utilized its accumulated PDP development and manufacturing technology to develop a unique slim-model vacuum insulated glass with a total thickness of approximately 6 mm, featuring insulation performance equivalent to triple argon-containing glass (total thickness approximately 3 cm).

2. No vacuum exhaust hole sealing component on glass surface, achieving smooth, flat appearance

In this exclusive new vacuum insulated glass manufacturing method developed by Panasonic, the exhaust hole sealing structure required to form a vacuum space between the two glass panes is not present on glass surface, which achieves a smooth, flat product appearance. This not only contributes to visual design, but also superior workability and ease of assembly with other components.

3. Lead-free vacuum sealing material ensures safety and environmental friendliness

The vacuum sealing material used by Panasonic in its PDPs achieved advanced vacuum maintenance and durability without using lead. The vacuum insulated glass also utilizes this vacuum sealing material to achieve lead-free status. That will give users peace of mind regarding safety and environmental friendliness throughout product lifetime for both household and commercial purposes.

Provided by Panasonic Corporation