Researchers make the slipperiest surfaces adhesive

The convenience of non-stick, Teflon-coated cookware is appreciated in kitchens worldwide, particularly by anyone doing the washing up. The chemical making up Teflon, polytetrafluoroethylene or PTFE, is one of the slipperiest materials known. Outside the kitchen, the low-friction surfaces and high chemical resistance of PTFE are essential to many applications across a range of industries. However, despite its usefulness, PTFE is difficult to work with. Making PTFE adhere to other types of materials requires harsh chemicals.

Now, a research team centered at Osaka University has developed a new way to make PTFE adhesive, and drastically improved the strength of its bonding with other materials. The findings were reported in Scientific Reports.

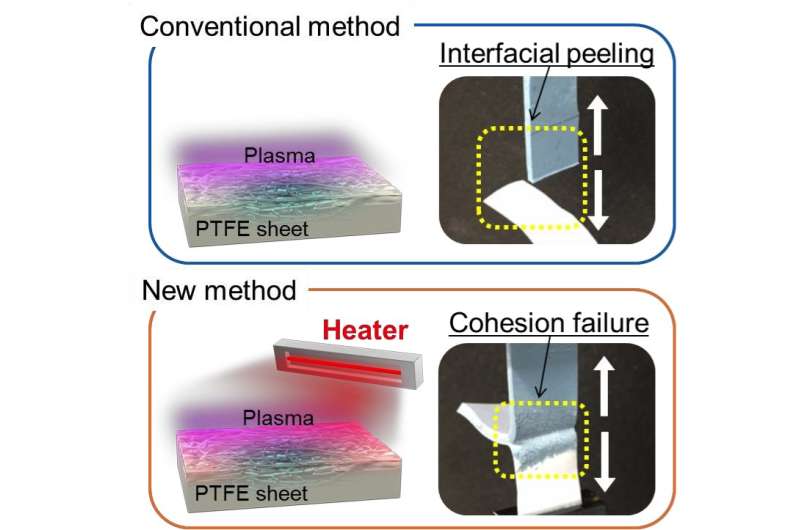

"People have been looking at how plasma treatments affect PTFE for some time, but no one has really examined how the treatments affect adhesion properties," study lead author Yuji Ohkubo explains. "With our plasma treatment, we improved the adhesion of the PTFE to some extent, but it was only when we combined this with extra heating of the PTFE that we saw it strongly adhering to rubber."

The team showed that adding a heating element to the chamber during the plasma treatment, to heat the PTFE, changed the surface structure, making it much harder. The heat and plasma-treated PTFE strongly adhered to the rubber surfaces.

"The real advantages of this work are that it avoids using some nasty chemicals and is relatively simple to implement," coauthor Kazuya Yamamura says. "In industrial processes, adding a heater to a plasma chamber is much easier than trying to adjust the temperature through the plasma power. We hope this new technique allows PTFE to be used in new ways that just weren't possible or practical before."

More information: Yuji Ohkubo et al, Drastic Improvement in Adhesion Property of Polytetrafluoroethylene (PTFE) via Heat-Assisted Plasma Treatment Using a Heater, Scientific Reports (2017). DOI: 10.1038/s41598-017-09901-y

Journal information: Scientific Reports

Provided by Osaka University