Researchers reveal the effect of nano-diamond on magnetorheological fluids

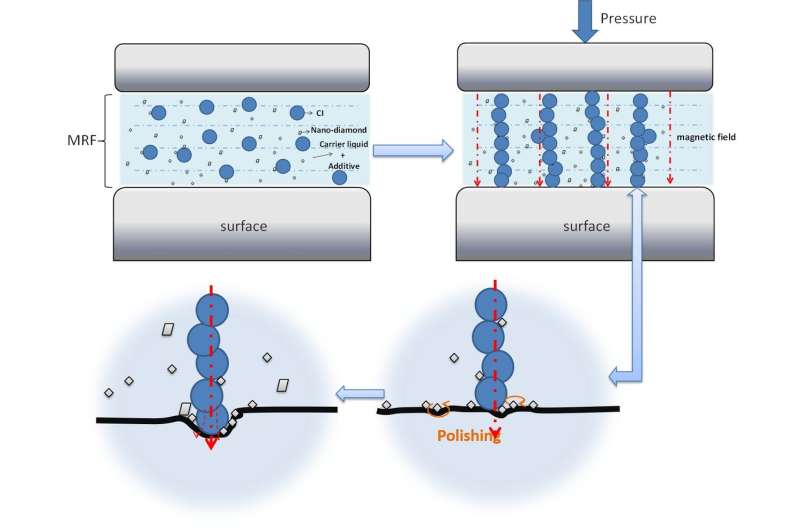

Chinese researchers have found that nano-diamond has significant impact on the performance of magnetorheological fluids (MRFs). The shear yield strength and settling stability of the MRFs were found to have potential to be highly enhanced through the process. The higher the strength of the magnetic field, the higher the difference in the shear yield strength.

In order to analyze the effects of nano-diamond on the performance of MRFs, the MRF-1 with a 2% mass fraction in nano-diamond and the MRF-2 without nano-diamond were prepared with the carbonyl iron powder in the dispersed phase and the synthetic mineral oil in the continuous phase. The viscosity and shear stress of MRFs under different magnetic fields were measured by the Anton-Paar rheometer (MCR 302). The MRF settling stability was studied by a standing observation method. A four-ball wear machine was utilized for the wear test at 0.1 T of magnetic field, whereas the magnetic field was provided by an external coil. Also, the three-dimensional white light interferometer was utilized to observe the surface of the ball wear spot, in order to determine the MRF friction properties.

The results demonstrated that the nano-diamond had a significant increase in surface wear. Both the shear yield strength and settling stability of the MRF could be highly enhanced.

The MRF preparation method containing the nano-diamond was simple and low cost, while apparently improved the settling stability of the MRF application and significantly increased the shear yield strength. This method broke the traditional bottleneck of MRFs and had important significance, but the device wear was more acute. Therefore, the MRF needs to be further improved. The research team is currently exploring preparation of high performance MRF.

More information: Mingmei Zhao et al, Effects of Nano-Diamond on Magnetorheological Fluid Properties, Nano (2017). DOI: 10.1142/S1793292017501193

Provided by World Scientific Publishing