New solid lubricant shown to reduce friction and wear on steel surfaces

Researchers have created a new type of non-liquid lubricant that has been shown to reduce friction and wear significantly under the extreme conditions found in various applications, from air compressors to missile systems.

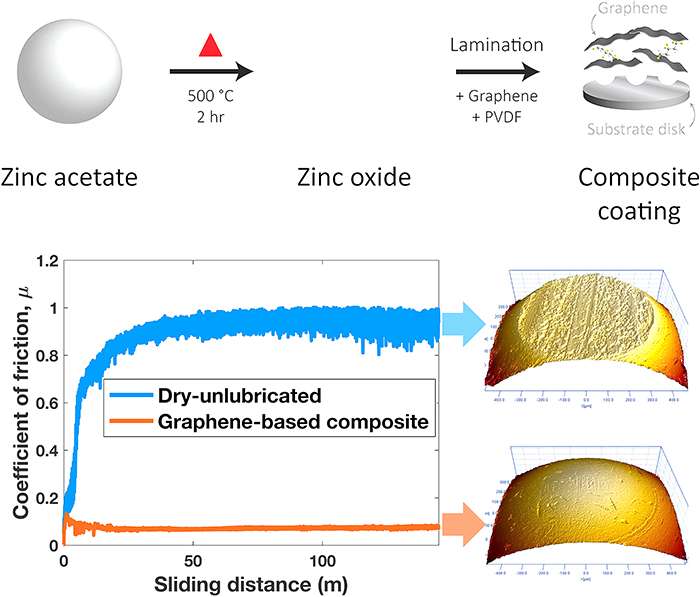

The new liquid-free composite is made from a slurry of a material called graphene, zinc oxide, and the polymer polyvinylidene difluoride. Graphene is an extremely thin layer of carbon that has many potential technological applications, including lubrication.

"It has superior thermal conductivity, high strength and provides ultralow friction," said Vilas Pol, an associate professor of chemical engineering at Purdue University.

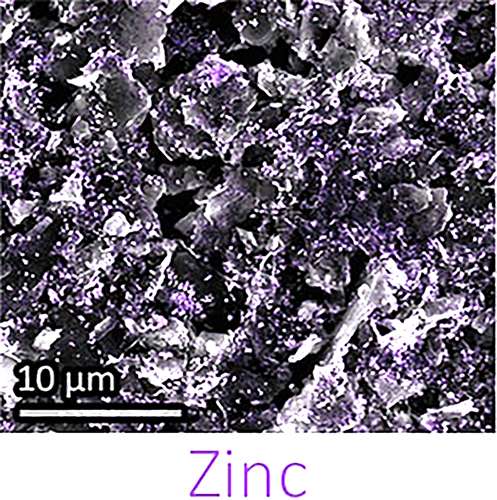

The nanosize zinc-oxide particles the team developed allow the lubricant to stick to the metal surface, and the polymer binds the whole mixture together, said chemical engineering graduate student Arthur Dysart.

Solid lubricants are needed for applications such as air compressors, equipment used in the food industry, space vehicles, gear-and-chain mechanisms, fasteners found in high-temperature environments, missile systems, high-speed printers, hydraulic motors in winches, cranes and military vehicles, high-performance shredders and drilling rigs.

"The fundamental causes of mechanical failure are friction and wear, so reducing these factors improves the performance and lifetime of many mechanical systems," said Farshid Sadeghi, Purdue's Cummins Distinguished Professor of Mechanical Engineering. "Despite recent advances, liquid lubricants cannot be used in situations of high temperature or low pressure such as a vacuum environment, so dry solid-state lubricants are a viable alternative to their liquid counterparts in extreme operating environments."

Researchers tested stainless-steel surfaces coated with the new lubricant.

"We tested it under worst-case scenarios," said mechanical engineering graduate student Abdullah A. Alazemi.

Findings were detailed in a research paper published on July 11 in the in the journal Carbon.

"The durability and resilience of this adhesive coating suggest exceptional potential as a dry lubricant for high load-bearing applications," Pol said.

The researchers found that the composite lubricant sets up a film that significantly improves friction and wear reduction. Raman spectroscopic analysis of wear scars revealed this persistent protective film on contact surfaces.

More information: Abdullah A. Alazemi et al. Novel tertiary dry solid lubricant on steel surfaces reduces significant friction and wear under high load conditions, Carbon (2017). DOI: 10.1016/j.carbon.2017.07.030

Journal information: Carbon

Provided by Purdue University