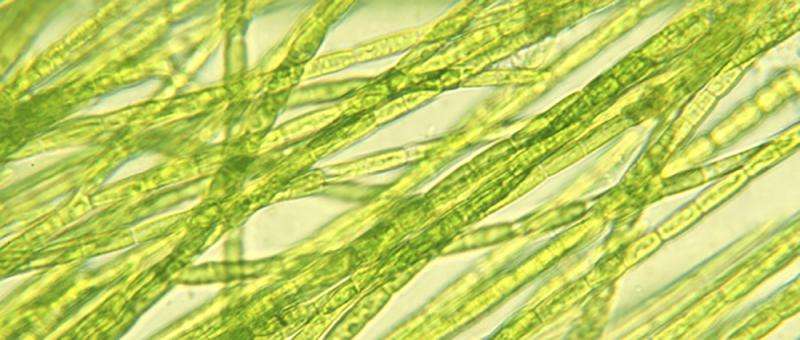

Technology could transform microalgae into bio-based chemicals to increase biofeedstock, reduce landfill waste

Gen3Bio Inc., a Purdue Foundry-affiliated company, is developing a unique process that could more effectively and affordably transform microalgae into bio-based chemicals to maximize the value of biofeedstock and reduce landfill waste.

"There's been a huge movement toward greener, renewable products for the sake of the environment and that includes biofuels and biochemicals," said Kelvin Okamoto, founder of Gen3Bio. "Conventional biofuels are derived from sugars of crops, which can take a considerable amount of land and water to produce. Algae has a low carbon footprint, is renewable and can be accessed in large quantities, so overall it is very environmentally friendly. It's a great alternative to meet the expected demand for bio-based products in the future."

Okamoto earned his Bachelor of Science and Ph.D. in chemistry from Stanford University and Cornell University, respectively. Through his company, Okamoto is scaling up and commercializing an effective, efficient and low-cost algae extraction method to lyse open the algae cells by using a mix of commercially available enzymes. Lysing open the cells releases and separates the fats, sugars and proteins within the cells. The different chemical components can be sold or further converted into bio-based chemicals, biofuels and bioplastics. The technology was developed at the University of Toledo.

Okamoto said algae has a wide variety of applications.

"Companies use algae for things such as wastewater treatment or flue gas remediation. Additionally, there are algae producers and harvesters who clean up fish farms or natural waters," he said. "Usually after the algae has been used for its initial purpose, it's disposed of in landfills or converted into animal feed supplements or field nutrition supplements. While the last two are great uses, companies do not receive much money from these options. It's more profitable to convert the byproduct algae to high value bio-based chemicals."

Okamoto said the most common current processes to extract biochemicals from algae often degrade a large portion of the cell contents and are energy intensive.

"The most common processes used today target the fats in the microalgae, which can then be used in biodiesel. However, these processes break down the sugars and proteins which can be valuable and utilized to produce bio-based chemicals," he said. "Petroleum-based diesel sells wholesale for about 15 cents a pound right now, so the companies producing only biodiesel have difficulty competing profitably because of this low cost. They lose money doing that."

Gen3Bio's process could allow companies to earn a profit on the sugars and proteins from the cells being sold to specialty chemical companies, with sales of biodiesel adding to revenue.

Gen3Bio is seeking funding to further develop the technology. Once the company finalizes the process, it plans to license the technology to its end users.

"We would offer a design and installation package for the equipment as well as an ongoing support package to licensees," Okamoto said. "Since most of the companies interested in this technology would be small, we would also distribute or consign byproduct bio-based chemicals upon request. This type of support would allow us to combine the resulting chemicals from these smaller facilities to get a larger, more attractive volume to the market."

Gen3Bio is a startup receiving assistance from the Purdue Foundry, an entrepreneurial accelerator located in Discovery Park's Burton D. Morgan Center for Entrepreneurship, and is located in the Purdue Research Park of West Lafayette.

"The Purdue Foundry has been critical in helping us craft our company message, attend networking opportunities and reach out for funding and apply for grants," Okamoto said. "Purdue is recognized as a great entrepreneurial support, which is why I decided to move the company to the area."

More information: gen3bio.biz/

Provided by Purdue University