Fundamental breakthrough in the future of designing materials

A team of researchers from AMBER centre based in Trinity College Dublin, have made a breakthrough in the area of material design - one that challenges the commonly held view on how the fundamental building blocks of matter come together to form materials.

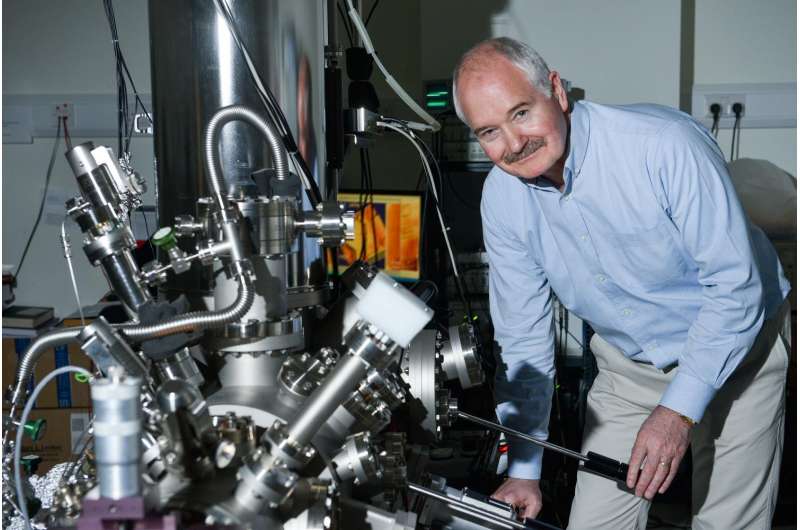

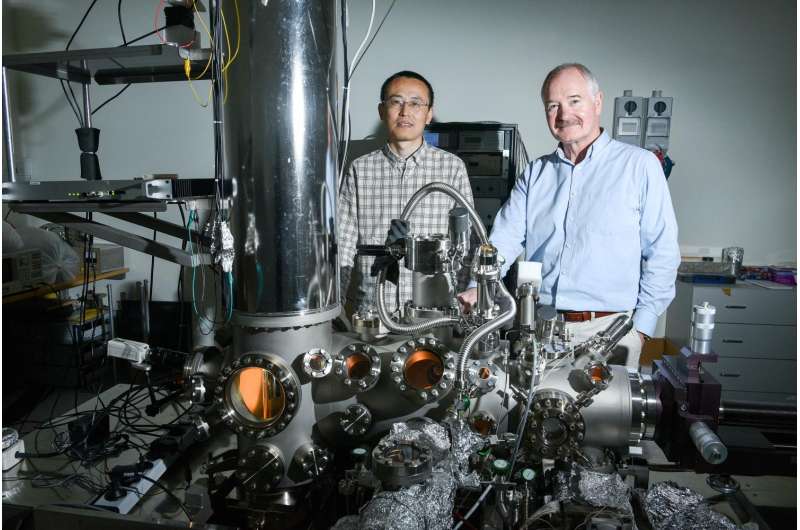

Professor John Boland, Principal Investigator in AMBER and Trinity's School of Chemistry, researcher Dr. Xiaopu Zhang, with Professors Adrian Sutton and David Srolovitz from Imperial College London and University of Pennsylvania, have shown that the granular building blocks in copper can never fit together perfectly, but are rotated causing an unexpected level of misalignment and surface roughness. This behaviour, which was previously undetected, applies to many materials beyond copper and will have important implications for how materials are used and designed in the future. The research was published today in the prestigious journal, Science. The Intel Corp. Components Research Group also collaborated on the publication.

Electrical, thermal and mechanical properties are controlled by how the grains in a material are connected to each other. Until now, it was thought that grains, which are made up of millions of atoms, simply pack together like blocks on a table top, with small gaps here and there. Professor Boland and his team have shown for the first time that nano-sized grains in copper actually tilt up and down to create ridges and valleys within the material. Nanocrystalline metals such as copper are widely used as electrical contacts and interconnects within integrated circuits. This new understanding at the nanoscale will impact how these materials are designed, ultimately enabling more efficient devices, by reducing resistance to current flow and increasing battery life in hand-held devices.

Professor John Boland, Principal Investigator in AMBER and Trinity's School of Chemistry, said, "Our research has demonstrated that it is impossible to form perfectly flat nanoscale films of copper and other metals. The boundary between the grains in these materials have always been assumed to be perpendicular to the surface. Our results show that in many instances these boundaries prefer to be at an angle, which forces the grains to rotate, resulting in unavoidable roughening. This surprising result relied on our use of scanning tunnelling microscopy which allowed us to measure for the first time the three-dimensional structure of grain boundaries, including the precise angles between adjacent grains."

He added, "More importantly, we now have a blueprint for what should happen in a wide range of materials and we are developing strategies to control the level of grain rotation. If successful we will have the capacity to manipulate material properties at an unprecedented level, impacting not only consumer electronics but other areas such as medical implants and diagnostics. This research places Ireland yet again at the forefront of material innovation and design."

More information: Zhang X, Han J, Plombon JJ, Sutton AP, Srolovitz DJ, Boland JJ. Nanocrystalline copper films are never flat. Science 28 July 2017 science.sciencemag.org/cgi/doi … 1126/science.aan4797

Journal information: Science

Provided by Trinity College Dublin