Cellulose nanofibers can help particles in ink and printed electronics disperse evenly

Drying is an important part of printing words and electronics. Particles suspended in liquid are applied to a surface and the liquid evaporates leaving the particles behind. Many times, the particles dry unevenly because of the so-called 'coffee ring effect'. Much like when spilled coffee dries up and leaves behind a hollow ring, particles tend to move to the outside of the liquid droplet. This is a problem, particularly for printed electronics, which require uniform application of a liquid for maximum performance.

Cellulose nanofibers offer an environmentally friendly and effective solution to this problem, explain researchers from Japan in a paper recently published in Science and Technology of Advanced Materials.

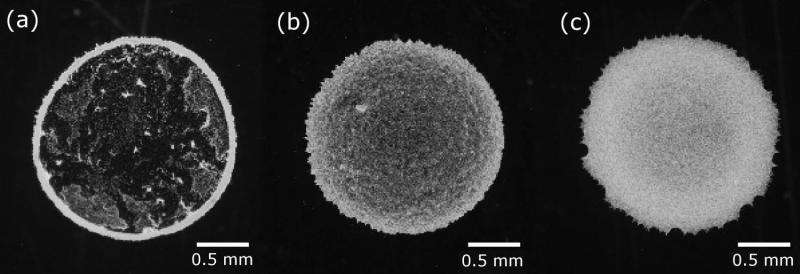

The researchers tested three different concentrations of cellulose nanofibers added to a solution with suspended particles. They also tried increasing the particle concentration in a solution with no added nanofibers. They photographed the drying process under a microscope over time.

The solutions with nanofibers dried much more evenly than those without. Instead of a hollow ring, the particles condensed into a solid dot, slightly shrinking in size as the liquid evaporated. Particles in the mixtures with nanofibers also moved at a consistent pace. There was no final rush to the periphery as was observed in the solutions without nanofibers.

The researchers conclude that cellulose nanofibers can improve the drying process and avoid problems stemming from uneven drying, such as degradation of paint coatings, clarity of printed characters on paper, and conductivity of printed electronics.

Once the solution dries, the nanofibers are left behind along with the desired particles. How the nanofibers impede or benefit material performance is a topic for further research.

"The addition of cellulose nanofibers may alter the electrical resistivity of conductive wires in the printed electronics, but the fine tuning of the concentration might be exploited for the control of electric resistivity itself," write the research team from Tokyo University of Agriculture and Technology, and Nagoya University.

More information: Yuto Ooi et al. Suppressing the coffee-ring effect of colloidal droplets by dispersed cellulose nanofibers, Science and Technology of Advanced Materials (2017). DOI: 10.1080/14686996.2017.1314776

Journal information: Science and Technology of Advanced Materials

Provided by National Institute for Materials Science