Nanomaterial makes laser light more applicable

Light is absorbed differently, depending on the material it shines on. An international research team including material scientists from Kiel University has created a complex hybrid material with the ability to absorb light with a unique broad range of wavelengths. In addition to that it scatters light which makes it really interesting for industrial applications. That could mean an important step in optoelectronic technologies towards laser light as a successor to LEDs. The results published in Nature Scientific Reports represent the output of a broad international collaboration, including scientists from Germany, Moldova, Denmark and Australia.

"As material scientists we are always in demand to develop nanomaterials that can absorb a wide range of light," explains Dr. Yogendra Mishra. He is leading an independent subgroup of the Functional Materials working group of Professor Rainer Adelung, Institute for Materials Science at Kiel University. This group has expertise in making tetrapods, four-armed zinc oxide structures. "We have now made tetrapods in a new way and created a hybrid material of carbon and inorganic material. It demonstrates the ability to absorb a broad range of wavelengths from ultraviolet to infrared – and it also diffuses light," Mishra explains. "The complex 3-D-tetrapod-architecture of our material spreads light in all directions."

This scattering effect of the hybrid material is urgently needed for using laser based lighting in optoelectronic technologies as in automobile industry. "Products of modern light technology should be as bright as possible without producing a lot of useless heat. That is the case with a normal bulb, which have almost become museum artefacts. The LEDs of today are better but powerful laser-based lights would be most efficient," says material scientist Mishra. The reason why Laser based lighting has not yet been realized for a broad application in industry is exactly its power, which could damage the eyes.

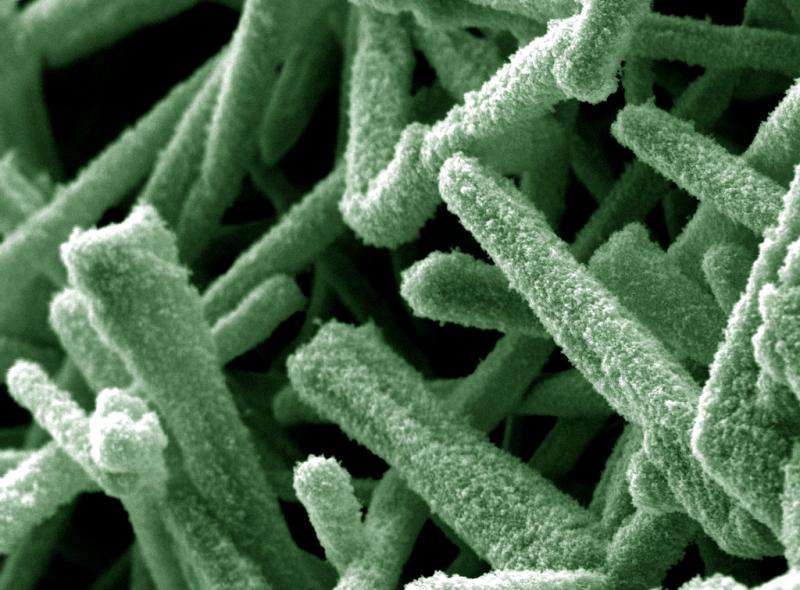

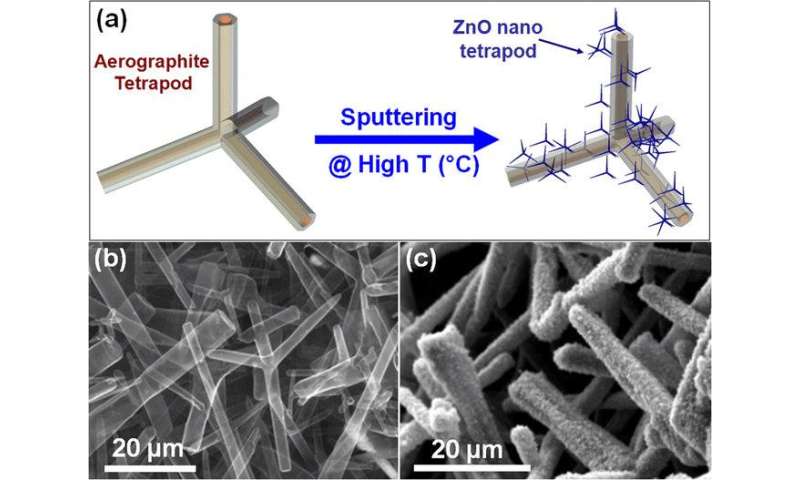

Therefore, the international research team tried to develop hybrid material elements which can degrade the brightness of laser light while maintaining its high power. That is the effect of the complex 3-D-tetrapod-architecture of the new hybrid material, developed in a close collaboration. At the Hamburg University of Technology (TUHH) the zinc oxide tetrapods from Kiel were transformed into aerographite tetrapods of carbon. A team from the Technical University of Moldova used its special sputtering machine to put a huge amount of smaller zinc oxide nanocrystals – also with the shape of tetrapods – on its surface. The result is a hybrid material with a fascinating spatial architecture consisting of Aerographite microtetrapods decorated with zinc oxide nanotetrapods. Colleagues from the University of Copenhagen and the University of Sydney investigated different properties of the newly developed nanomaterial.

"The zinc oxide-Aerographite hybrid architectured materials are technologically very important and our goal was to develop cost-effective approaches for their fabrication as well as to achieve a proper understanding of their unique properties," says Professor Ion Tiginyanu, Director of the National Centre for Materials Study and Testing at the Technical University of Moldova. Used as a scattering element, the research team is convinced that the material is a very promising candidate for optoelectronic technologies, especially since the technological process behind it is simple and economical.

-

The scattering behaviour of the new nano hybrid material (generated by a laser pointer with green light) degrades the brightness of laser light. That way it becomes more applicable for industry. Credit: Yogendra Mishra -

Dr. Yogendra Mishra from Kiel University shows the scattering property of the new nano hybrid material of carbon and zinc oxide. Credit: Julia Siekmann, CAU -

The laser light spreads over the material instead of concentrating on just one point. Credit: Julia Siekmann, CAU

More information: Ion Tiginyanu et al. Strong light scattering and broadband (UV to IR) photoabsorption in stretchable 3D hybrid architectures based on Aerographite decorated by ZnO nanocrystallites, Scientific Reports (2016). DOI: 10.1038/srep32913

Journal information: Scientific Reports

Provided by Kiel University