Manufacturing – Improved welding

Oxide removal for welding can be laborious and costly, yet results from a new study indicate the preparation may be unnecessary for certain solid-state joining.

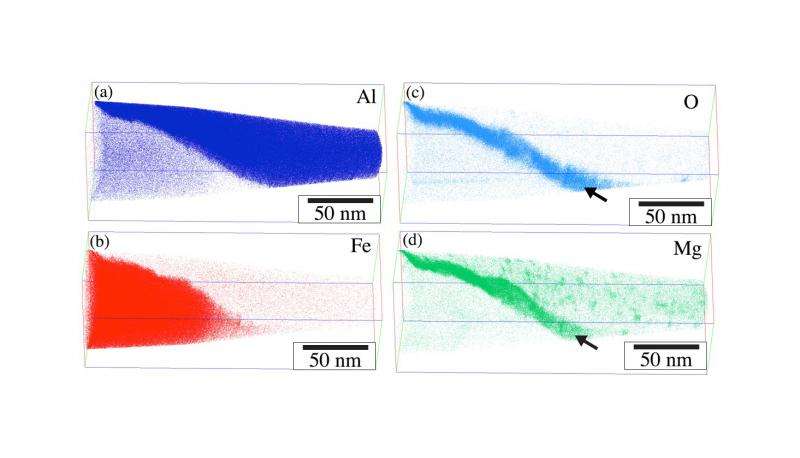

An Oak Ridge National Laboratory-led research team evaluated the atomic behavior of iron and aluminum when joined through solid-state welding to determine the fate of resulting oxide film build-up, a part of the process not well researched.

Solid-state welding, one of the oldest and most prominent joining techniques, begins with atomically clean materials that are free of oxides or impurities.

Through deformation and frictional heating below the melting point, metal sections are joined completely in the solid state.

"We determined that the oxide film is not merely 'scraped off' as previously thought, but in fact dissolves in the material being welded near the surface," ORNL's Niyanth Sridharan, lead author, said. Details of the study were published in Scripta Materialia.

More information: N. Sridharan et al. Colossal super saturation of oxygen at the iron-aluminum interfaces fabricated using solid state welding, Scripta Materialia (2017). DOI: 10.1016/j.scriptamat.2016.11.040

Journal information: Scripta Materialia

Provided by Oak Ridge National Laboratory