New metallic glass bounces: The secret is to make it almost—but not quite—unstructured

Engineers have created a new material with an unusual chemical structure that makes it incredibly hard and yet elastic.

The material can withstand heavy impacts without deforming - even when pushed beyond its elastic limits, it doesn't fracture, instead retaining most of its original strength. That makes it potentially useful in a variety of applications from drill bits to body armor for soldiers to meteor-resistant casings for satellites.

In the journal Scientific Reports, researchers from USC; the University of California, San Diego; and Caltech announced the creation of the material, which was produced by heating a powdered iron composite up to exactly 630 degrees Centigrade (1166 degrees Faherenheit) and then rapidly cooling it.

"In particular, the fact that the new materials performed so well under shock loading was very encouraging and should lead to plenty of future research opportunities," said Veronica Eliasson, lead author of the paper and assistant professor at the USC Viterbi School of Engineering.

Dubbed SAM2X5-630, the new material has the highest impact resistance of any "bulk metallic glass" - a class of artificially generated materials first discovered in the 1960s that possess disproportionate strength, resilience, and elasticity due to their unusual chemical structure.

Typical metals and metal alloys have an organized, crystalline structure at the atomic level. Bulk metal glasses (BMGs, for short) are formed when metal and metal alloys are subjected to extreme heat and then rapidly cooled - exciting their atoms into disorganized arrangements, and then freezing them there.

In general, BMGs tend to be strong, resist scratching, tough to fracture, and highly elastic. One commercially available zirconium-based BMG is pound-for-pound twice as strong as titanium.

"Thanks to Professor Eliasson's expertise in shocks and high velocity testing, we were able to observe the remarkable elastic limit of this material at high velocities, a behavior which was not evident from conventional mechanical tests," said Andrea Hodge, principle investigator of the project and professor at USC Viterbi.

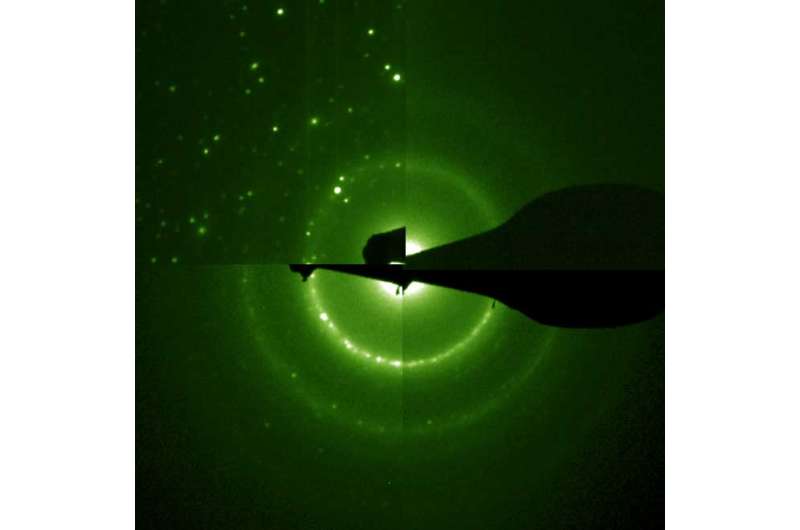

What makes SAM2X5-630 special is that it's not entirely a glass - just mostly. For some reason, the exact timing and temperatures used to create it leave just a few hints of structure here and there - which seems to be the key to its unique nature. The exact same iron composite heated and cooled slightly differently yields a completely random atomic arrangement that lacks the impressive elastic properties.

"It has almost no internal structure, like glass, but you see tiny regions of crystallization," Eliasson said. "We have no idea why a small amount of crystalline regions in these bulk metallic glasses makes such a big difference under shock loading."

The Hugoniot Elastic Limit (the maximum shock it can take without irreversibly deforming) of a 1.5-1.8 mm-thick piece of SAM2X5-630 was measured at 11.76 ± 1.26 GPa.

For reference, stainless steel has an elastic limit of 0.2 GPa, while that of tungsten carbide (a high-strength ceramic used in military armor) is 4.5 GPa. This isn't to say that SAM2X5-630 has the highest elastic limit of any material known; diamonds top out at a whopping 60 GPa, they're just not practical for many real-world applications.

The material was produced at UC San Diego using a spark-plasma sintering process in which the iron compound is powdered, placed in a dye, and then zapped with a current - superheating it to the point of binding without ever liquefying it.

Eliasson and Hodge collaborated with former PhD student Gauri Khanolkar of USC, Michael Rauls of Caltech, and James Kelly and Olivia Graeve of the Jacobs School of Engineering at UC San Diego.

More information: Gauri R. Khanolkar et al. Shock Wave Response of Iron-based In Situ Metallic Glass Matrix Composites, Scientific Reports (2016). DOI: 10.1038/srep22568

Journal information: Scientific Reports

Provided by University of Southern California