Making the invisible visible: Color-changing indicators highlight microscopic damage

Damage developing in a material can be difficult to see until something breaks or fails. A new polymer damage indication system automatically highlights areas that are cracked, scratched or stressed, allowing engineers to address problem areas before they become more problematic.

The early warning system would be particularly useful in applications like petroleum pipelines, air and space transport, and automobiles - applications where one part's failure could have costly ramifications that are difficult to repair. Led by U. of I. materials science and engineering professor Nancy Sottos and aerospace engineering professor Scott White, the researchers published their work in the journal Advanced Materials.

"Polymers are susceptible to damage in the form of small cracks that are often difficult to detect. Even at small scales, crack damage can significantly compromise the integrity and functionality of polymer materials," Sottos said. "We developed a very simple but elegant material to autonomously indicate mechanical damage."

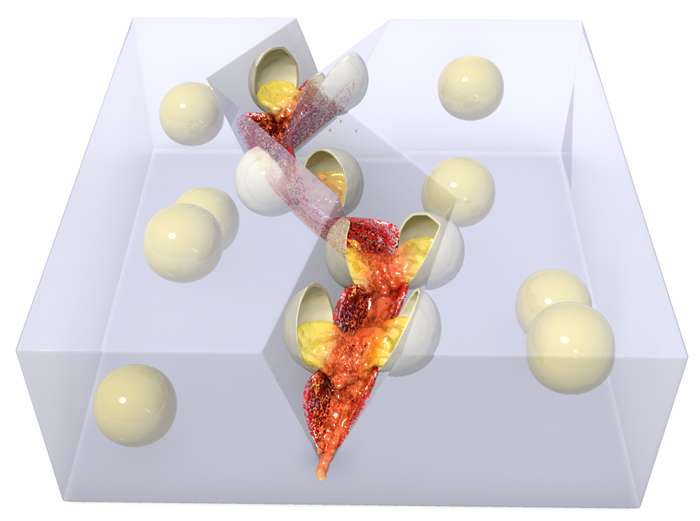

The researchers embedded tiny microcapsules of a pH-sensitive dye in an epoxy resin. If the polymer forms cracks or suffers a scratch, stress or fracture, the capsules break open. The dye reacts with the epoxy, causing a dramatic color change from light yellow to a bright red - no additional chemicals or activators required.

The deeper the scratch or crack, the more microcapsules are broken, and the more intense the color. This helps to assess the extent of the damage. Even so, tiny microscopic cracks of only 10 micrometers are enough to cause a color change, letting the user know that the material has lost some of its structural integrity.

""Detecting damage before significant corrosion or other problems can occur provides increased safety and reliability for coated structures and composites," White said. White and Sottos are affiliated with the Beckman Institute for Advanced Science and Technology at the U. of I.

The researchers demonstrated that the damage indication system worked well for a variety of polymer materials that can be applied to coat different substrates including metals, polymers and glasses. They also found that the system has long-term stability - no microcapsule leaking to produce false positives, and no color fading.

In addition to averting unforeseen and costly failure, another economic advantage of the microcapsule system is the low cost, Sottos said.

"A polymer needs only to be 5 percent microcapsules to exhibit excellent damage indication ability," Sottos said. "It is cost effective to acquire this self-reporting ability."

Now, the researchers are exploring further applications for the indicator system, such as applying it to fiber-reinforced composites, as well as integrating it with the group's previous work in self-healing systems.

"We envision this self-reporting ability can be seamlessly combined with other functions such as self-healing and corrosion protection to both report and repair damage," Sottos said. "Work is in progress to combine the ability to detect new damage with self-healing functionality and a secondary indication that reveals that crack healing has occurred."

More information: Advanced Materials, onlinelibrary.wiley.com/doi/10 … /adma.201505214/full

Journal information: Advanced Materials

Provided by University of Illinois at Urbana-Champaign