Industry 4.0 and additive manufacturing

At the World Economic Forum (WEF) in Davos a key topic is focusing on the "Digital Transformation of Industries". The fourth industrial revolution is imminent. It goes by the name "Industry 4.0" and is expected to fundamentally change, among other things, the production methods and business models currently used in industrialized countries. Experts estimate that Industry 4.0 will result in virtual data merging with real production equipment. The resulting "smart factory" will bring customers and suppliers closer together, as production orders will be sent by the customer directly to the machine, and the production data will be transferred to the distribution partner in real time. Manufacturing will become leaner and faster and respond to customers' needs.

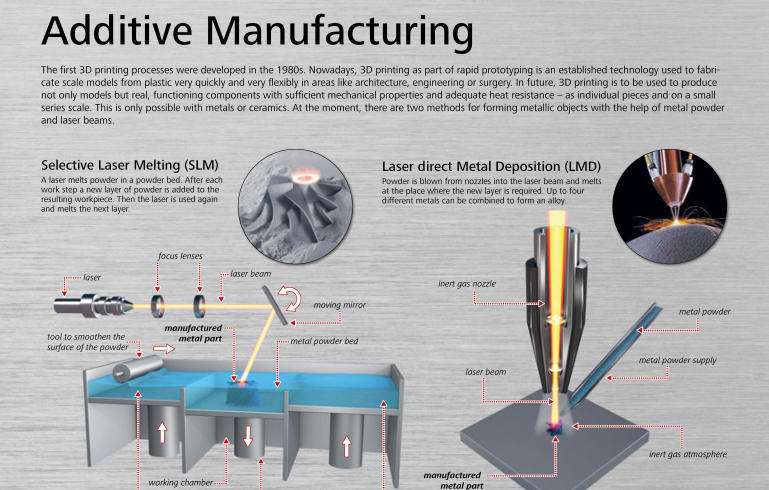

Additive Manufacturing – 3D printing in metal

A key component in making Industry 4.0 a reality are machines that can produce the desired components faster, more flexibly and more precisely than ever before. Less prototype construction, fewer dies, less post-processing. In future it will have to be possible to turn data into components and products at an incredible speed.

3D printers give a sneak preview of what this type of production might look like. The first of these devices were created in the 1980s, and nowadays you can buy entry-level devices for less than 700 Swiss francs. But so far, 3D printers have generally been used to make objects from plastic. The mechanical properties and the temperature stability of these objects are pretty limited as a result, which is why they are mainly used for illustrative purposes, i.e. as visual models. This is why 3D printing is often described as "rapid prototyping".

For the fourth industrial revolution, the technique used for 3D printing will have to go one step further: from rapid prototyping to Advanced Manufacturing, the production of lasting and functional components with defined mechanical and thermal properties: products made from metals or ceramics.

Empa, the Swiss Federal Laboratories for Materials Science and Technology, is working on this topic with various research groups. One group is examining the optimized use of lasers, while another is researching new types of alloys that this technology makes feasible for the first time. A further lab is using Additive Manufacturing to build new, geometric forms that were not possible up to now with the traditional production methods available.