Polymer breakthrough could revolutionize water purification

We've all seen the Febreze air fresheners, which employ a derivative of corn starch to trap invisible air pollutants in the home and remove unwanted odors.

A team of Cornell researchers has used the same material found in Febreze, cyclodextrin, to develop a technique that could revolutionize the water-purification industry.

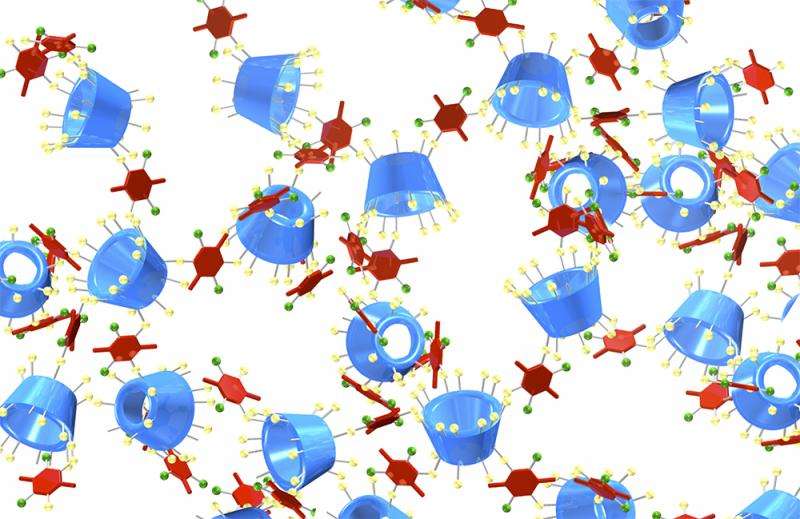

The team is led by Will Dichtel, associate professor of chemistry and chemical biology and a 2015 MacArthur Foundation Fellowship winner. His group invented a porous form of cyclodextrin that has displayed uptake of pollutants through adsorption at rates vastly superior to traditional activated carbon – 200 times greater in some cases.

Activated carbons have the advantage of larger surface area than previous polymers made from cyclodextrin – "more sites for pollutants to stick to," Dichtel said – but they don't bind pollutants as strongly as cyclodextrin.

"What we did is make the first high-surface-area material made of cyclodextrin," Dichtel said, "combining some of the advantages of the activated carbon with the inherent advantages of the cyclodextrin. When you combine the best features of those two materials, you get a material that's even better than either class.

"These materials will remove pollutants in seconds, as the water flows by," he said, "so there's a potential for really low-energy, flow-through water purification, which is a big deal."

What's more, the cyclodextrin-containing polymer features easier, cheaper regeneration, so it can be reused many times with no observed loss in performance.

The results of approximately 18 months of work are published online in Nature on Dec. 21.

Support for the work came from the National Science Foundation through the Center for Sustainable Polymers, which brings together a diverse team of researchers from Cornell, the University of Minnesota and the University of California, Berkeley, to discover high-performance materials from sustainable, non-petroleum-based sources.

Following the discovery of the cyclodextrin polymer, additional support to scale up and build prototype filtration systems has been provided by Cornell's Atkinson Center for a Sustainable Future.

Research began shortly after the NSF grant was awarded. It wasn't long before Dichtel's team identified the cyclodextrin polymer as showing promise in water purification. After spending a few more months analyzing the material, Dichtel reached out to Damian Helbling, assistant professor of civil and environmental engineering. Helbling's areas of study include water quality as it relates to human and ecosystem health.

"My role at that initial stage, last January or February, was a consultant," said Helbling, a co-author of the paper. "They said, 'We have this polymer that can do this; what are the water quality issues to which this could be applied?'"

Helbling noted that his group challenged the polymer in a way that Dichtel's group hadn't, to see if it would adsorb various pollutant mixtures at lower concentrations relevant for real-world water purification.

"[Our contribution was] proving that even under environmentally relevant conditions, the phenomena that they were observing were repeatable. And they were," Helbling said.

Recyclability is another advantage of the cyclodextrin polymer, Dichtel said. Whereas activated carbon filters must undergo intense heat-treating for regeneration, cyclodextrin filters could be washed at room temperature with methanol or ethanol. And a drop-off in performance following regeneration wasn't observed, Dichtel said.

Dichtel, whose MacArthur Foundation "Genius Award" will total $625,000 over five years, said part of that award will go to further research into cyclodextrin water purification, ultimately setting the stage for a product that can be manufactured on large scales.

"Traditionally, that gap between the laboratory discovery and getting something out in the world where it can help people is difficult to bridge," he said. "So to have support that is totally unrestricted, that can be used pragmatically in that space, is really valuable."

Dichtel is excited about the potential his group's results show in terms of the water-purification industry.

"There are a lot of things going for it," he said. "There are still some unknowns, but everything looks pretty promising."

More information: Alaaeddin Alsbaiee, et al. Rapid removal of organic micropollutants from water by a porous β-cyclodextrin polymer Nature (2015) DOI: 10.1038/nature16185

Journal information: Nature

Provided by Cornell University