Microplotter system prints DNA, proteins, live cells on a range of fragile materials

A University of Wisconsin-Madison spinoff that was spawned during an effort to make DNA-based computers has just introduced a low-cost instrument that can print dots and lines just 5 to 10 millionths of a meter across.

Instruments made by SonoPlot, Inc., of Middleton, Wisconsin, can be programmed by drawing lines on a computer screen. That ease, combined with a unique ability to print a wide range of liquid materials, makes the SonoPlot machine useful in many realms of research and development, says company president Brad Larson.

Some of SonoPlot's finest marks are invisible to the unaided eye.

Larson cofounded the company after earning master's and doctoral degrees in materials science from UW-Madison. When SonoPlot opened its doors in 2005, biology was the original sales focus.

"The system is gentle enough to print DNA, proteins, even live cells, on a range of fragile materials that are often disturbed during other types of printing," Larson says. "Our customers have printed artificial spider silk, artificial proteins, and 'gene chips,' which detect specific genetic sequences."

Today, many sales emerge from the ability to print electrical conductors, Larson says. "The biggest application is printed electronics, prototyping and direct printing of circuits, and testing various designs without needing a lab or processing."

At UW-Madison, physics Professor Michael Winokur has used a SonoPlot machine to print an all-polymer light-emitting diode (LED). The plotters can print radio frequency identification (RFID) tags, and have built the first all-printed nanotube transistor. Nanotubes are an advanced form of carbon that are the subject of feverish scientific interest.

Several of the devices have gone to U.S. national security organizations, Larson says. In an effort to reduce civilian casualties, Army researchers printed a fuse-antenna combination intended to prevent a warhead from exploding until it had traveled a certain distance.

The printers are also being used to create antennas for terahertz radiation, an electromagnetic signal that can pass through some materials but lacks the harmful ionizing effect of X-rays. If the antennas work as predicted, "you might be able to image broken bones in the field without worrying about radiation," says Larson.

Because the SonoPlot's driver uses high-frequency sound, it can print a far wider range of liquids, suspensions and emulsions than other microprinters.

The invention that enabled SonoPlot's technology was made in the lab of UW-Madison material science and engineering Professor Max Lagally in the early 2000s, who was working with chemistry Professor Lloyd Smith on computers that would calculate with the information-storage molecule DNA.

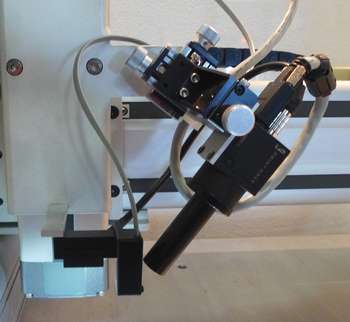

Lagally wanted to place dots of DNA on a surface. He, Larson and two others investigated a dispenser driven by ultrasound (sound with a frequency above human hearing), and in 2004, patented the core of SonoPlot's device: a conical tube, with vibrations oriented along its long axis.

The result was an applicator that could gently and precisely dispense many types of liquids without touching the surface, Lagally says. "The conical tip was Brad's idea, and we very quickly found that using a piezoelectric actuator, we could make fluid flow out of the end."

Piezoelectric devices convert electric current into vibration.

The system has several advantages over inkjet printers, Lagally says. The lines have straight edges, not serrated ones. The surface is not disturbed by a spray of ink. And the ultrasound mobilizes many substances that would clog an inkjet.

The invention was patented by the Wisconsin Alumni Research Foundation and is licensed to SonoPlot. SonoPlot has four employees and distributors in Canada, China and India, with sales worldwide.

The company has sold more than 100 units, each made to order, since 2007. SonoPlot can sell at a cost below other microprinting equipment because the invention is "terrifically simple," Lagally says. "The only thing that's new is the conical shape; it's patented and it's making money for the university."

As 3-D printing gets more popular, Larson suggests it might be combined with biologic or electronic elements deposited with a SonoPlot to make entirely new objects.

At this point, however, speed is the biggest challenge, Larson adds. "We have a system that is great for R&D and rapid prototyping, but once you have developed a circuit, then you want to go into light production. So now, what can you use?"

More information: www.sonoplot.com/

Provided by University of Wisconsin-Madison