Printing with nanomaterials a cost-friendly, eco-friendly alternative

Researchers at Binghamton University are focusing on printed electronics: using inkjet technology to print electronic nanomaterials onto flexible substrates. When compared to traditional methods used in microelectronics fabrication, the new technology conserves material and is more environmentally friendly.

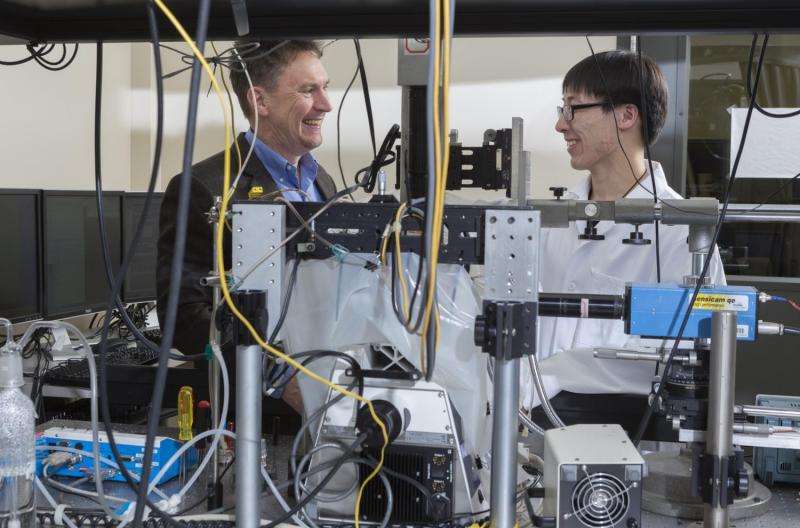

Think of inkjet printing and you'll likely picture an old printer in an office. Not so if you're Timothy Singler, director of graduate studies and professor of mechanical engineering at Binghamton University. In the Transport Sciences Core at the Innovative Technologies Complex, Singler is collaborating with Paul Chiarot and Frank Yong, assistant professors of mechanical engineering, to study inkjet printing of functional materials.

Functional materials are categorized in terms of the actions they can perform rather than on the basis of their origins. Solution-processed materials may have electrical, optical, chemical, magnetic, thermal or other functionalities. For example, silver is strongly electrically conductive and can be formulated into nanoparticle ink. However, Singler explains that printing with solution-processed nanomaterials instead of traditional inks is significantly more complex.

"One really has to study how nanomaterials deposit on a substrate—what structures they form, how you can control them—because you're dispersing the nanomaterials into a liquid so you can print them, and that liquid volatilizes, leaving only the material on the substrate. But the evaporation process and capillarity cause very complex flows that transport the material you're trying to deposit in nonintuitive ways," Singler says. "These flows have to be controlled to achieve an optimal functional structure at the end."

Provided by Binghamton University