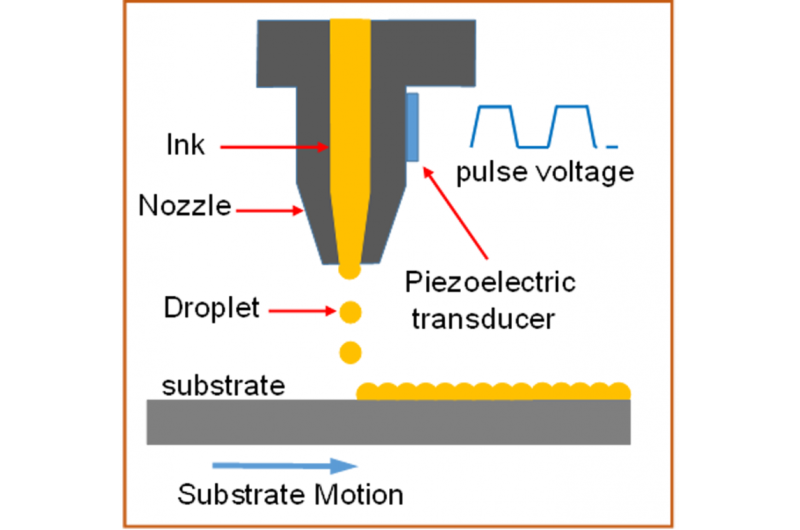

Inkjet printing process for kesterite solar cells

A research team at HZB has developed an inkjet printing technology to produce kesterite thin film absorbers (CZTSSe). Based on the inkjet-printed absorbers, solar cells with total area conversion efficiency of up to 6.4% have been achieved. Although this is lower than the efficiency records for this material class, the inkjet printing minimizes waste and has huge advantages for industrial production.

The drop-on-demand inkjet printing is a promising approach allowing patterning of materials with negligible materials waste; hence, significant reduction of raw materials cost can be achieved. Furthermore, inkjet printing can be easily adapted to a roll-to-roll process, which is suitable for large scale production. From the industrial application perspective, both of these two features of the inkjet printing technology are of great interest. A critical requirement for using inkjet printing is to develop a suitable ink in terms of viscosity and stability which leads to compact and homogeneous films.

Tuning the molecular ink

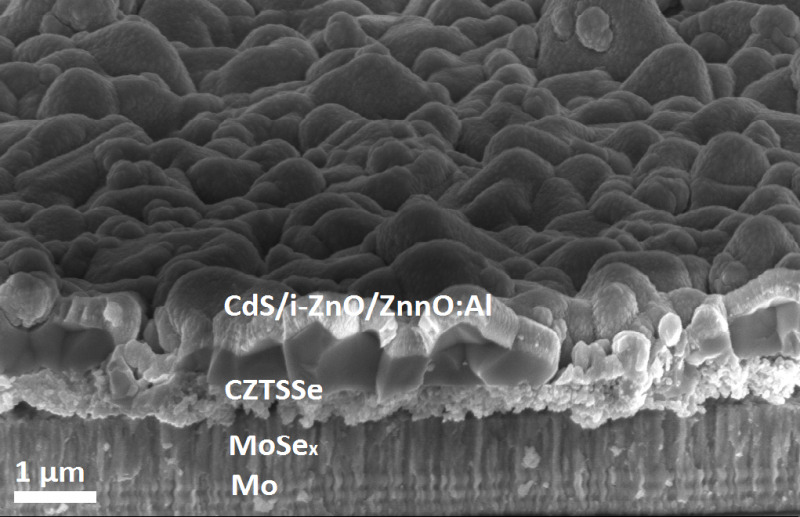

Dr. Xianzhong Lin from the Institute for Heterogeneous Material Systems of HZB used a molecular ink which was originally developed for spin coating technologies. The ink is produced by dissolving Cu, Zn, Sn metal salt and thiourea in dimethyl sulfoxide solvent. Lin tested its suitability for inkjet printing. He found that the viscosity of the ink can be tuned by adjusting the ink concentration and the ink composition can also be easily controlled by adding or reducing the amount of each chemical added. The CZTSSe absorbers were formed by annealing the inkjet-printed Cu-Zn-Sn-S precursor film under an atmosphere containing Selenium.

Economical process

Initial optimization of the processing conditions such as ink composition and printing parameters have already yielded solar cells with efficiencies up to 6.4%. The huge advantage of inkjet printing versus spin coating to obtain thin film absorbers is the lesser amount of waste: Whereas with spin coating, a large quantity of the ink material is wasted, the inkjet printing is very economical: For example, less than 20 microliter ink is needed to build up a micrometer CZTSSe thin film absorber on an inch by inch substrate in this study.

Low toxicity and low waste

"Although the solar cell performance is still far below the record efficiency of 12.7% for CZTSSe based solar cells, the great advantage of our approach is the low toxic and low material wastage process", Prof. Martha Lux-Steiner explains. The team is now working on the optimization of processing conditions for the kesterite absorbers to further improve the solar cell performance and on the deposition of buffer and TCO layers by inkjet printing. The goal is to print a complete device with high efficiency without relying on expensive vacuum technology. This work opens up a promising route for the fabrication of kesterite thin film solar cells.

More information: The results of this work have now been published in X. Lin, J. Kavalakkatt, M. C. Lux-Steiner, A. Ennaoui, Inkjet-printed Cu2ZnSn(S, Se)4 solar cells, Adv. Sci. 2015. DOI: 10.1002/advs.201500028

Provided by Helmholtz Association of German Research Centres