Inspired by venus flytrap, researchers develop folding 'snap' geometry

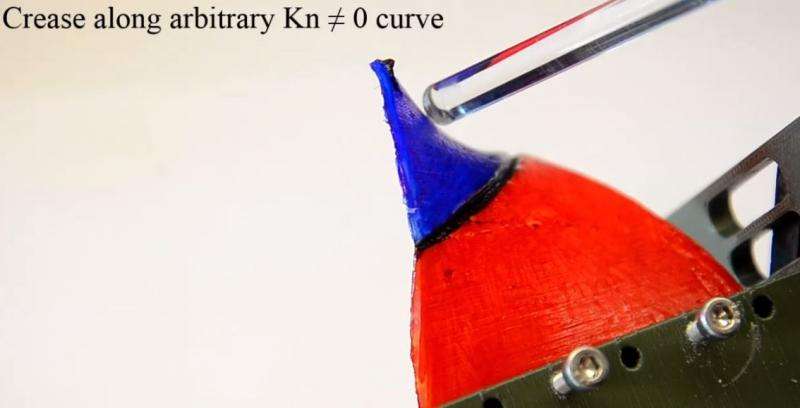

Inspired by natural "snapping" systems like Venus flytrap leaves and hummingbird beaks, a team led by physicist Christian Santangelo at the University of Massachusetts Amherst has developed a way to use curved creases to give thin curved shells a fast, programmable snapping motion. The new technique avoids the need for complicated materials and fabrication methods when creating structures with fast dynamics.

The advance should help materials scientists and engineers who wish to design structures that can rapidly switch shape and properties, says Santangelo. He and colleagues, including polymer scientist Ryan Hayward, point out that until now, there has not been a general geometric design rule for creating a snap between stable states of arbitrarily curved surfaces.

"A lot of plants and animals take advantage of elasticity to move rapidly, yet we haven't really known how to use this in artificial devices," says Santangelo. "This gives us a way of using geometry to design ultrafast, mechanical switches that can be used, for example, in robots." Details of the new geometry appear in an early online issue of Proceedings of the National Academy of Sciences.

The authors point out, "While the well known rules and mechanisms behind folding a flat surface have been used to create deployable structures and shape transformable materials, folding of curved shells is still not fundamentally understood." Though the simultaneous coupling of bending and stretching that deforms a shell naturally gives items "great stability for engineering applications," they add, it makes folding a curved surface not a trivial task.

Santangelo and colleagues' paper outlines the geometry of folding a creased shell and demonstrates the conditions under which it may fold smoothly. They say the new technique "will find application in designing structures over a wide range of length scales, including self-folding materials, tunable optics and switchable frictional surfaces for microfluidics," such as are used in inkjet printer heads and lab-on-a-chip technology.

The authors explain, "Shape programmable structures have recently used origami to reconfigure using a smooth folding motion, but are hampered by slow speeds and complicated material assembly." They say the fast snapping motion they developed "represents a major step in generating programmable materials with rapid actuation capabilities."

Their geometric design work "lays the foundation for developing non-Euclidean origami, in which multiple folds and vertices combine to create new structures," write Santangelo and colleagues, and the principles and methods "open the door for developing design paradigms independent of length-scale and material system."

More information: Geometrically controlled snapping transitions in shells with curved creases, Nakul Prabhakar Bende, DOI: 10.1073/pnas.1509228112

Journal information: Proceedings of the National Academy of Sciences

Provided by University of Massachusetts Amherst