July 15, 2015 feature

Fastest-ever flexible diode provides 'last missing piece' needed to realize bendable phones

(Phys.org)—While there are hints that Samsung and LG are developing flexible phones that can fold, roll up, and even be stretched into larger screens, there are still some obstacles to overcome before such bendable phones become a reality. Arguably the largest obstacle is the need for a high-speed flexible diode, which is what detects and modulates the cell phone's signal. The diode must operate at high speeds in order to match the transmission frequencies used by wireless cellular communication, Bluetooth, Wi-Fi, and GPS signals (which range from 935 MHz to 5 GHz).

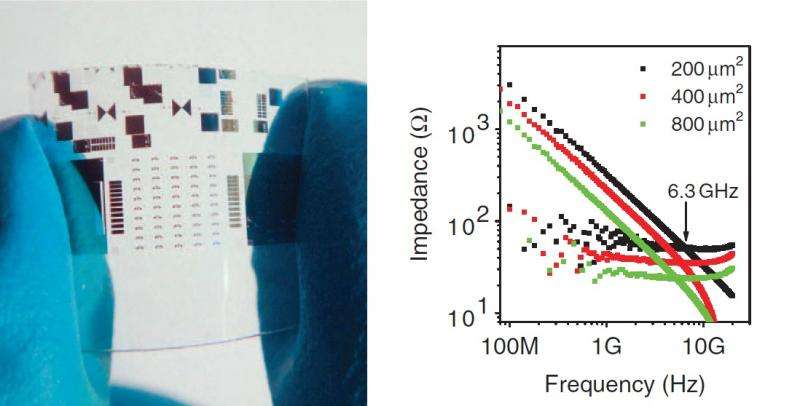

In a new paper published in Nature Communications, a team of researchers led by Professor Aimin Song at the University of Manchester in the UK with collaborators at Shandong University in China have developed a flexible Schottky diode that achieves a speed of 6.3 GHz, which to the best of their knowledge makes the device the fastest of its kind to date. It is also the first flexible diode to reach what is widely considered the "benchmark speed" of 2.45 GHz, which covers the principal frequency bands used in most current wireless communications, with the exception of 4G and the newest 5G Wi-Fi channels.

"A flexible GHz diode is the last missing jigsaw piece needed to achieve flexible mobile phones and rapidly growing wearable electronics," Song told Phys.org. "Thin-film IGZO transistors have already been demonstrated that operate at frequencies beyond 100 MHz, which is enough to construct mobile phone chips for data processing in at least entry-level smart phones. Now having a fast-enough diode for front-end signal receiving and modulation shall bring the flexible mobile phones that were envisaged many years ago much closer to the market."

In the new study, the researchers fabricated the diode using the flexible semiconductor film indium-gallium-zinc-oxide (IGZO). They demonstrated the high-speed operation using low-temperature processing on flexible substrates, which has not been achieved before now. The previous best IGZO Schottky diodes could achieve speeds of up to 3 GHz, but could not be made on flexible plastic substrates because they used high-temperature processing, and so could only be fabricated on glass substrates. The previous best flexible Schottky diodes, which were made of crystalline silicon microparticles, obtained speeds of up to 1.6 GHz but still required complex and expensive processing.

One of the keys to achieving the high-speed flexible diode was controlling the IGZO thickness to optimize performance. As the researchers explained, it is very surprising that this could be done at all, as it has been thought that a thick IGZO layer is essential for high-speed operation due to having a low capacitance. Here the researchers found that, in fact, the series resistance increases as IGZO thickness increases, which plays a critical role in determining the diode speed. While the researchers initially expected that the thickest IGZO layer would have the best performance, they found that it actually exhibits the worst performance. By investigating the factors underlying this surprising finding—which include the relationships between resistance, reactance, and capacitance—the researchers could optimize the diode's performance by using an 80-nm-thick IGZO layer.

With a better understanding of the IGZO semiconductor material's electronic properties, the researchers were able to create a promising component of next-generation phone technology. They expect that post-treatment processes could further improve the diode's performance—both its speed and its output voltage, which is necessary to maintain a strong signal.

"Our future research will focus on integration of the fast diodes and transistors for a range of demo circuits, or even simple systems, in order to demonstrate the amazing potential of flexible thin-film electronics," Song said.

More information: Jiawei Zhang, et al. "Flexible indium-gallium-zinc-oxide Schottky diode operating beyond 2.45 GHz." Nature Communications. DOI: 10.1038/ncomms8561

Journal information: Nature Communications

© 2015 Phys.org