Undersea pipes "shoulder" anchoring duties

Research off the north-west coast shows undersea pipelines tend to bury themselves in the seabed quicker than expected after they are deployed, resulting in potential cost savings for the petroleum industry.

A UWA engineer says the resource industry spends up to $1.6 million per kilometre to prevent undersea pipelines from moving during cyclones.

PhD candidate Simon Leckie says some of this could be saved if designers better understood the way subsea pipelines bury themselves in the ocean floor.

"The process that's going on here is equivalent to what happens when you stand in the surf on the beach and your feet bury themselves into the sand," he says.

He says petroleum engineers worry about possible oil spills caused by cyclone damage and pipe's tendency to "snake" when charged with high-pressure fluids.

"You can dump a lot of rocks on top of the pipe so it stays where you want it to be," Mr Leckie says.

"You can put anchors in, you can put concrete weight coating onto the pipe.

"If we can understand self-burial or self-lowering of pipelines better we might be able to rely on that initial lowering of the pipe into the seabed to ensure the pipe's stability."

He examined seven years' worth of data from routine inspections at Woodside's North West Shelf project which used a remote-controlled submarine known as an ROV (Remotely Operated Vehicle), equipped with video cameras and a sonar.

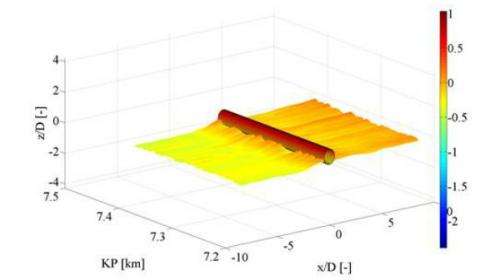

Data showed tides were vigorous enough to start undermining pipes immediately, causing them to settle.

However this scouring often created a column of water under the pipe, which had to span a space without solid support.

If this space is large enough, it causes the pipe to sag.

The pipelines were found to sink into "shoulders" of solid seabed on either side of the spanned space, creating further stability by anchoring the pipe.

Mr Leckie also found the newly-created spaces under the pipeline had a predictable maximum size, given the known tidal data and ocean floor density.

"There's a lot of work done on erosion of sediments around objects in laboratories and in numerical modelling," Mr Leckie says.

"But there's been very little work done in comparing those results to full-scale scour out in the field.

"If you can show similar results at full-scale then you're able to have more confidence in the work you're doing at small scale."

This research could make similar projects in the region much cheaper.

More information: Simon H.F. Leckie, Scott Draper, David J. White, Liang Cheng, Antonino Fogliani, "Lifelong embedment and spanning of a pipeline on a mobile seabed," Coastal Engineering, Volume 95, January 2015, Pages 130-146, ISSN 0378-3839, dx.doi.org/10.1016/j.coastaleng.2014.10.003.

Provided by Science Network WA