Japan researchers target 3D-printed body parts

Japanese scientists say they are on their way to being able to create custom-made skin, bone and joints using a 3D printer.

Several groups of researchers around the world have developed small masses of tissue for implants, but now they are looking to take the next step and make them functional.

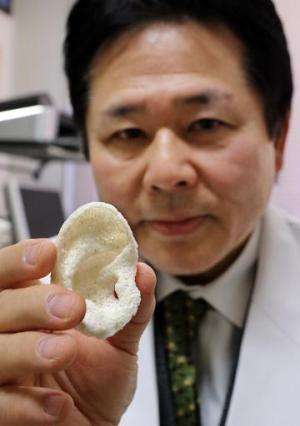

Tsuyoshi Takato, a professor at the University of Tokyo Hospital, said his team had been working to create "a next-generation bio 3D printer", which would build up thin layers of biomaterials to form custom-made parts.

His team combines stem cells—the proto-cells that are able to develop into any body part—and proteins that trigger growth, as well as synthetic substance similar to human collagen.

Using a 3D printer, they are working on "mimicking the structure of organs"—such as the hard surface and spongy inside for bones, Takato said.

In just a few hours, the printer crafts an implant using data from a Computer Tomography (CT) scan.

These implants can fit neatly into place in the body, and can quickly become assimilated by real tissue and other organs in the patient, the plastic surgeon said.

"We usually take cartilage or bone from the patient's own body (for regular implants), but these custom-made implants will mean not having to remove source material," Takato said.

The technology could also offer hope for children born with bone or cartilage problems, for whom regular synthetic implants are no good because of the rate of their body's growth.

The main hurdle was the heat generated by conventional 3D printers, which damages living cells and protein.

"We haven't fully worked out how to avoid heat denaturation but we already have some models and are exploring which offers the most efficient method," he told AFP.

The artificial protein Takato and his team use was developed by Fujifilm, which has been studying collagen used in photographic films.

Since it is modelled on human collagen and does not derive from animals, it can be easily assimilated in human bodies, reducing the risk of infections such as mad-cow disease.

Takato said the team aims to start clinical tests of 3D-printed skin in three years and then proceed to bones, cartilages and joints.

Researchers say their previous project on the custom-made "CT-Bone", developed with Tokyo-based firm Next 21 and governmental institutions, gave a hint to this latest study.

That technique uses calcium phosphate, the substance that makes up real bones, but does not contain stem cells.

CT-Bone implants are inserted into broken bones, or places where the bone is missing, to act as a scaffolding for new bone growth.

That new growth can overtake the implant after two years, with the host bone serving as an incubator.

Animal tests have suggested regeneration could be even quicker for implants that use collagens, stem cells and growth stimulus, Takato said.

Japanese medical authorities are expected to grant approval for putting CT-Bone to practical use this year.

© 2015 AFP