June 23, 2012 report

Canon's Mixed Reality System may speed design cycles

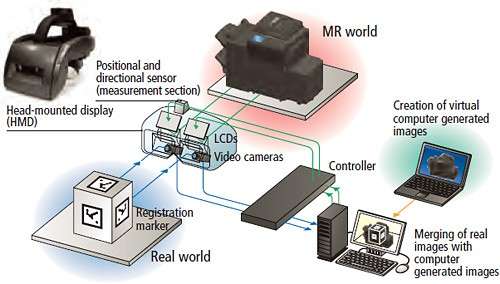

(Phys.org) -- Canon this week announced a new augmented reality system—headset and software. The new system is to allow virtual prototypes to replace physical ones. Three-dimensional computer generated images can instantly change based on the user’s movements. The Mixed Reality (MR) System is being initially promoted as an industrial design tool where, for example, the head-set-wearing user gets to see a computer-generated image of a car on a set of real tires, all in realtime. Two video cameras inside the head-mounted display (HMD), each in front of right and left eyes, capture the real-world video which is sent to a connected computer, processing the merge between real and virtual.

Even though the images are delivered through a video feed, by matching the video cameras' optical axes with those of the light entering the eyes from the small displays, the system delivers a realistic experience, says the company, creating the impression that visuals are being seen with the naked eye. Through image processing, positioning and directional sensor data, the information that results is shown on monitors inside the HMD.

Canon, Tokyo-based specialists in imaging and optical products, will focus on the MR System’s use in industrial auto design as a tool to speed up the design process. The MR system is considered as an easy fit in this kind of environment, especially for designers who are assigned to work in teams to get a sense of how their product may look and serve in the real world. Making use of 3-D CAD data, a team can share ideas and view product images during collaboration. Interactivity can be put to use, with the viewed virtual system being manipulated with the help of control wands.

“As product lifecycles grow progressively shorter, it has become increasingly necessary for the manufacturing industry to introduce products to the market in a timely manner,” says the company press release; the system can be a support tool for quicker evaluation of design and operability. “The system can reduce the number of prototypes required and can contribute to minimizing costs.”

Canon’s marketers recognize that in time the potential applications of the system can travel far beyond industry assembly lines. One suggestion has been as a tool used in medicine, to enact surgical procedure simulations. Another has been for customer-vendor interactions in sales scenarios where the customer can see the product from different angles and perspectives, as in home and office renovations.

The product will be available only in Japan, from late July. Canon plans to offer an SDK for developers.

More information:

Press release

© 2012 Phys.Org