Energy from ceramics

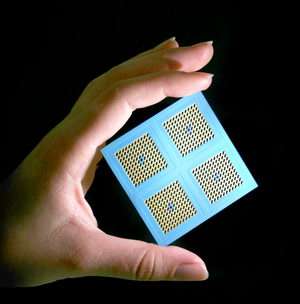

Micro fuel cells are already being acclaimed as an alternative to batteries. However, producing them from hundreds of tiny separate parts is complex and expensive. An alternative is now available: ceramic fuel cells that can be manufactured in one piece.

You’ve specially taken your laptop computer along so you can work while you travel, but before you’ve accomplished anything worthwhile, the battery has gone flat. The bugbear of notebook technology has always been its power supply. Developers have heralded micro fuel cells as the solution to the tiresome problem of mobile power supplies, but despite all their promises, not a single affordable miniaturized fuel cell is yet available for everyday use.

One reason for this situation, believes Dr. Michael Stelter of the Fraunhofer Institute for Ceramic Technologies and Systems IKTS in Dresden, is that the tiny power sources are put together from hundreds of filigree parts: “That makes them complicated to develop and expensive to manufacture.” The researcher and his colleagues are therefore pursuing a completely new approach, producing fuel cells from a new type of ceramic film called LTCC – Low Temperature Co-fired Ceramic. The material has been in use in the chip industry for some time as a substrate for microelectronic components.

The Fraunhofer researchers have successfully developed cost-effective ways of integrating additional “non-electronic functional elements” into the ceramics. Their task is facilitated by a special feature of the material: Structures can be applied not only to the surface of the ceramic, but also to the inside. The micro fuel cells are criss-crossed with tiny channels that transport hydrogen or fluids.

They are simple and cheap to produce, says Stelter: “We can produce a fuel cell out of LTCC in one go. Not only is the process economical – it is reliable as well.” A further advantage is that the LTCC fuel cell can run on various types of fuel – mainly hydrogen and methanol, but also less conventional fuels such as formic acid. “Formic acid is an excellent power source, but it corrodes ordinary fuel cell materials”, says Stelter. The ceramic material, in contrast, is resistant to the acid. The researchers are pressing ahead with the new generation of micro fuel cells in collaboration with several German industrial enterprises. They are already using the LTCC technology to manufacture other products that will make their market debut much sooner: tiny pressure sensors with integrated electronics, for instance, or microtitre plates for use in biochemical assays.

Source: Fraunhofer-Gesellschaft