New technique could bring quality-control tool for nanocomposites

Layered nanocomposites containing tiny structures mixed into a polymer matrix are gaining commercial use, but their complex nature can hide defects that affect performance.

Now researchers have developed a system capable of detecting such defects using a "Kelvin probe" scanning method with an atomic force microscope. The ability to look below the surface of nanocomposites represents a potential new quality-control tool for industry.

"This is important for anything having polymers that contain small structures, including photovoltaics for solar cells, organic conducting devices for flexible electronics, battery materials and so on," said Arvind Raman, the Robert V. Adams Professor of Mechanical Engineering and associate dean for the Global Engineering Program at Purdue University.

Nanocomposites are layered materials containing various structures such as carbon nanotubes, ultrathin sheets of carbon called graphene, gold nanoparticles and graphite nanofibers, mixed into a polymer matrix.

"We need a tool that permits us to see how these nano-objects are distributed within a polymer matrix," Raman said. "You may look at the whole film and say, 'Well, it isn't performing as advertised,' but you don't know why. This allows you to see under the surface in a non-destructive manner."

Findings appeared in the February issue of ACS Nano, published by the American Chemical Society. The paper was authored by doctoral student Octavio Alejandro Castañeda-Uribe, from Universidad de los Andes (Uniandes) in Colombia; Ronald Reifenberger, a Purdue professor of physics; Raman; and Alba Avila, an associate professor in the Electrical and Electronic Department at Uniandes who is affiliated with the microelectronics center (CMUA) there.

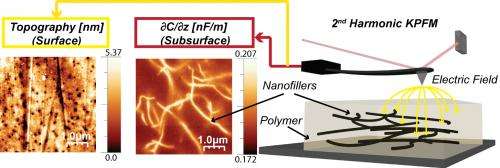

The Kelvin probe method has been used to map electrical charge on the surfaces of materials. However, now researchers have discovered that the method can be used to look below the surface, detecting three-dimensional networks of nanostructures embedded deep inside the polymer matrix.

"This allows us to correlate these networks with the multifunctional properties of nanocomposites," Avila said.

An atomic force microscope uses a tiny vibrating probe called a cantilever to yield information about materials and surfaces on the scale of nanometers, or billionths of a meter. The instrument enables scientists to "see" objects far smaller than possible using light microscopes. In Kelvin probe scanning an alternating current is applied to the sample being studied, causing the probe to vibrate at a certain frequency, and then a direct current is applied to the probe, partially nullifying the effect of the alternating current.

"You nullify the main frequency, but it turns out there is a second frequency that is not nulled," Raman said. "You kind of mute the main signal, but there is a higher tone that remains in the cantilever, and that higher tone is very sensitive to what's underneath the surface."

The new findings identify precisely how deeply and through how many layers the method can probe into a material. Researchers developed computational methods and an experimental technique making the tool possible.

"If the nanocomposite doesn't work well, you have to be able to look inside," Raman said. "You have to do quality control at the nanoscale."

Nanotubes and other nanostructures should ideally be well distributed throughout the nanocomposite, forming a continuous network. However, the structures tend to clump together instead, hindering performance.

"So, now we can see where they are clumping together and where they are not because you can see below the surface without destroying the sample," he said.

The method also allows researchers to determine the orientation, connectivity and size distribution, or the particle-to-particle variation of size, which is important for quality control.

Images created with the method show wormlike carbon nanotubes below the surface of a composite. The researchers systematically added layers and showed that the method is capable of detecting structures down to a depth of about 400 nanometers.

Purdue worked with researchers at Uniandes in Bogotá through the Colombia-Purdue Institute, which fosters partnerships among Purdue and institutions in Colombia, including universities, companies, government ministries and nongovernmental organizations.

"It's a good example of how you bring international teams together to get something really good accomplished," Raman said.

Uniandes researchers were involved in processing the nanocomposite films and also developing the experimental technique. Nanocomposite film processing and development of the atomic force microscope experimental technique were carried out by a team at Purdue's Birck Nanotechnology Center. The computations were carried out at Uniandes.

"This collaboration made it possible to provide research training and access to facilities at both universities for advanced research focused on exploring depth-detection limits of characterization techniques based on atomic force microscopy," Avila said. "These limits are needed to confidently detect, characterize, and quantify the location of the nanomaterial networks within a polymer matrix, allowing 3-D image reconstruction of nanocomposites and a more reliable prediction, estimation and correlation of the properties of nanocomposites."

More information: "Depth-Sensitive Subsurface Imaging of Polymer Nanocomposites Using Second Harmonic Kelvin Probe Force Microscopy." ACS Nano, 2015, 9 (3), pp 2938–2947 DOI: 10.1021/nn507019c

Journal information: ACS Nano

Provided by Purdue University