February 13, 2015 feature

Scientists go to great lengths to extend superlow friction

(Phys.org)—When nanosized pieces of graphite slide against each other, there can be virtually no friction between them. For many years, superlow friction, or "superlubricity," was known to exist only on the nanoscale. Then in 2012, scientists first demonstrated superlubricity beyond the nanoscale when they discovered the phenomenon in micrometer-sized graphite. Building on this and related research, scientists in a new study have now theoretically shown that superlow friction could extend to lengths of tens of centimeters.

In the new study published in Physical Review Letters, researchers Ming Ma, et al., have theoretically investigated the maximum length of a chain of particles that exhibits superlubricity. Their model shows that this critical length depends on the experimental parameters and the material's properties, especially its stiffness. For very stiff materials, such as carbon nanotubes, the scientists found that superlubricity may hold for up to tens of centimeters, after which it abruptly disappears.

"These results indicate an avenue for achieving superlow friction at the macroscale, and can potentially aid in the rational design of superlubric materials for nanomechanical applications," Michael Urbakh, a professor at Tel Aviv University and one of the study's lead authors, told Phys.org.

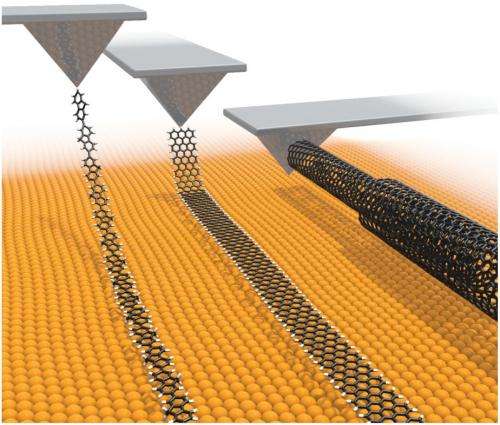

As the scientists explain, superlow friction relies on a special arrangement of atoms on a material's surface. In graphite, for instance, the surface atoms have a bumpy hexagonal arrangement like egg cartons/boxes. In certain orientations, two surfaces of graphite can mesh in such a way that the "bumps" can slide past one other effortlessly, and friction drops to almost zero.

In contrast, when the same pieces of graphite are slightly rotated with respect to each other, their surface atoms can no longer easily slide, and the materials exhibit the familiar effects of friction.

This kind of change in geometrical configuration can explain the abrupt transition between the frictionless and friction regimes in the researchers' models. A shorter nanotube, or chain, exhibits superlubricity because its particles are mismatched, or incommensurate, with the underlying substrate atoms. Since the atoms avoid interlocking with each other, the chain easily slides on the surface. But for a longer chain, a mechanical instability triggers lattice matching at the chain's leading edge. As a result, the particles become in registry, or commensurate, with the atoms in the substrate lattice, and friction suddenly increases.

The researchers' simulations also revealed that the critical chain length forms a sharp boundary between two phases based on interparticle distance: the distance between particles is smaller in the shorter chain than in the longer chain. At exactly the critical length, an abrupt jump in this distance occurs, along with the abrupt jump in friction.

By better understanding superlubricity and its limits, the researchers hope to extend the effect to as large a scale as possible. Superlubricity could prove very useful for designing nanoscale systems with low wear and tear, and it could be even more useful if it could be extended to larger scales.

"The challenge here is to scale up the size of the sliding objects without losing the perfect egg-box geometry necessary for superlubricity," said coauthor Andrea Vanossi at the CNR-IOM Democritos National Simulation Center and the International School for Advanced Studies (SISSA), both in Trieste, Italy. "Normally, as the size of the objects grows, defects and imperfections comes into play. Only recently, thanks to the impressive advances in the synthesis techniques, has it been possible to produce defect-free, atomically perfect elongated nanostructures such as carbon nanotubes, graphene nanoribbons, and conjugated polymers. Once it is possible to have two large-scale, geometrically perfect surfaces rub against each other without friction, and to apply this material as a coating to ball bearings and moving machine parts, there will be huge savings ahead in the areas of energy, resource consumption, and maintenance."

The researchers are currently working to expand their approach to understand mechanisms limiting superlow friction between 3D materials.

More information: Ming Ma, et al. "Critical Length Limiting Superlow Friction." Physical Review Letters. DOI: 10.1103/PhysRevLett.114.055501

Journal information: Physical Review Letters

© 2015 Phys.org