Conductive nanofiber networks for flexible, unbreakable, and transparent electrodes

Transparent conductors are required as electrodes in optoelectronic devices, such as touch panel screens, liquid crystal displays, and solar cells. Currently, the transparent conductors used for such applications are made of indium tin oxide (ITO).

However, ITO-based transparent electrodes are brittle, prone to breakage, and expensive. Therefore, there is strong demand for alternatives to ITO transparent electrodes .

Tokyo Institute of Technology researchers report the first development of a facile method for the fabrication of flexible and unbreakable transparent electrodes using nanofibers.

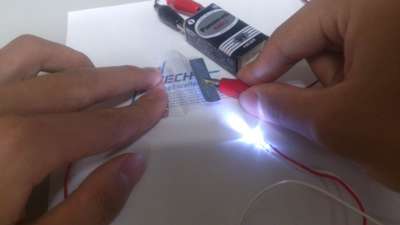

Two-dimensional aluminum (Al) nanofiber networks offering transparent conductors were fabricated by simple wet chemical etching of Al metalized polymer films using an electrospun polystyrene nanofiber mask template.

The resulting Al nanowire networks—with a width of 500 nm and an area fraction of 22.0 % —exhibited 80 % optical transmittance and sheet resistance of 45 Ω sq-1, figures of merit that are comparable to conventional transparent conductors. Notably, the fabrication method developed by the Tokyo Tech group is scalable for mass production and cost effective.

The resulting flexible, unbreakable, and transparent electrodes are promising for applications in both large-scale and mobile optoelectronic devices including ones that are flexible. Examples of applications are large displays, large interactive touch screens, photovoltaic solar panels, light-emitting diode panels, smart phones, and tablets.

More information: Keisuke Azuma, Koichi Sakajiri, Hidetoshi Matsumoto, Sungmin Kang, Junji Watanabe, and Masatoshi Tokita. "Facile fabrication of transparent and conductive nanowire networks by wet chemical etching with an electrospun nanofiber mask template." Materials Letters, 115, 187-189 (2014) (DOI): 10.1016/j.matlet.2013.10.054

Journal information: Materials Letters

Provided by Tokyo Institute of Technology