Local nanoscale electrical measurements for graphene

Research from the National Physical Laboratory (NPL), Royal Holloway, University of London, and Linköping University, Sweden, has taken an important step towards standardising important electrical parameters of graphene such as surface potential and work function. The nascent graphene industry requires these standardised measurements so that the properties of graphene are understood well enough for it to be widely used in commercial electronic devices.

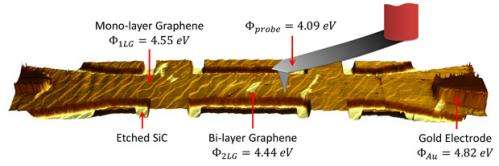

Surface potential and work function measurements can be used for defining local (down to the nanoscale) electrical properties of single layer and bilayer graphene. This is important as, while current manufacturing techniques can produce sheets of 95% single layer graphene, even small amounts of bilayer graphene in a sample can change the electrical characteristics and affect the performance of devices.

Currently, the numerical values obtained by commonly used techniques can vary significantly and are not reliable enough to make accurate comparisons. While substrate and environmental conditions can affect the results, there are also specific instrumental problems caused by the use of different measurement methods.

This new research published in Scientific Reports, the open-access journal from Nature Publishing Group, compares the accuracy and resolution of three commonly used measurement techniques: frequency-modulated Kelvin probe force microscopy (FM-KPFM); amplitude-modulated Kelvin probe force microscopy (AM-KPFM); and electrostatic force spectroscopy (EFS). The results show that frequency-modulated techniques such as FM-KPFM and EFS give more accurate results of the surface potential, as well as higher spatial resolution, than commonly used amplitude-modulated KPFM.

Olga Kazakova, who led the work at NPL, said:

"We have shown that there are significant differences in the accuracy and resolution of the most commonly used techniques for making these measurements. This means that a lab using a frequency-modulated technique will get different values than another lab using an amplitude-modulated technique, for example. This makes it difficult to have confidence in the values and define graphene characteristics."

The paper then presents a route to the standardisation of graphene measurements made in ambient conditions, rather than in vacuum, as these conditions are more representative of the environments found in general research laboratories and industry. For example, for the studied devices the obtained work function values are 4.55±0.02 eV and 4.44±0.02 eV for single layer and bilayer graphene, respectively. It should be noted that these values are not absolute and would depend on a number of intrinsic and extrinsic parameters. However, the proposed method allows for accounting of variable environmental conditions and doping variations and provides the accurate measure of the graphene surface potential, work function and carrier concentration.

The results will improve the ability of science and industry to express the characteristics of graphene quantitatively and with increased confidence. The proposed standardised technique can also be used for many other electronic materials such as semiconductors and photovoltaics, ensuring an impact not only on the graphene industry but also in the wider world of electronics.

The paper is titled "Standardization of surface potential measurements of graphene domains."

More information: www.nature.com/srep/2013/13090 … /full/srep02597.html

Journal information: Scientific Reports

Provided by National Physical Laboratory