Upsalite: Scientists make 'impossible material'... by accident

Researchers in Uppsala, Sweden accidentally left a reaction running over the weekend and ended up resolving a century-old chemistry problem. Their work has led to the development of a new material, dubbed Upsalite, with remarkable water-binding properties. Upsalite promises to find applications in everything from humidity control at home to chemical manufacturing in industry.

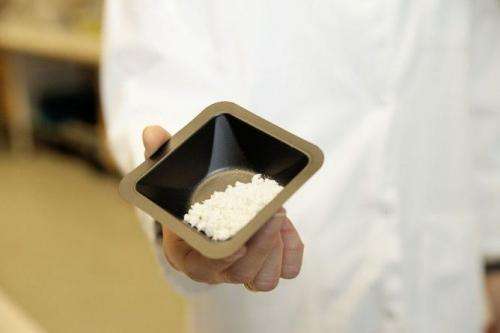

Maria Strømme and colleagues at Uppsala University, whose work appears in the journal PLOS ONE, have modified a procedure dating back to 1908 to make a powdered and dry form of magnesium carbonate (MgCO3). The reaction ingredients are all cheaply available: magnesium oxide (MgO) and carbon dioxide (CO2), dissolved in methanol, a common industrial solvent. The result is pure, dry MgCO3.

Dry in this case means very dry. In the chemical sense, it means void of almost any water molecules at all.

Crystalline forms of dry MgCO3, which lack the structure needed to absorb water, are readily synthesised at high temperatures (over 100 °C). As early as 1820, people started to search for lower-temperature routes to make dry MgCO3, but none have successfully yielded pure product until now. This is why Upsalite has been described as an "impossible material".

The key modification was to increase the pressure of CO2 to three times that of normal atmospheric pressure, rather than simply bubbling the gas through a mixture of MgO in methanol. When one mixture was accidentally allowed to react over a long weekend, researchers came back to find a gel. It turns out the gel was formed because methanol molecules had been trapped within the material. When heated to 70 °C, which is above the boiling point of methanol, the gel "solidifies and collapses into a white and coarse powder". Analysis confirmed that the product was just what chemists had been trying to make for more than 100 years – a dry, powdered form of MgCO3.

Upsalite has impressive properties as a desiccant, absorbing water better than the much more expensive materials that are currently used (called zeolites). Most of the absorbed water is retained when Upsalite is transferred from a humid to a very dry environment. The dry form can be regenerated by heating to 95 °C. By contrast, most zeolites need to be heated to over 150 °C in order to dry them. Not only is Upsalite easy to make and reuse, but it is also not toxic to humans, which makes it suitable for humidity control indoors.

The impressive drying property stems from the very large internal surface area of Upsalite. MgCO3 is a common mineral that occurs in a variety of forms, most of which have water bound to their surface and are crystalline. By contrast, Upsalite has no water integrated into its structure and is not crystalline. Instead, it is mesoporous – a structure with pores that are a million times smaller than the width of a human hair – which provide it with a much greater surface area.

The past 20 years have seen a surge of interest in mesoporous materials such as zeolites and carbon nanotubes due to their ability to selectively absorb small molecules, which may enable applications in drug delivery, pollution removal, and the development of new catalysts for chemical reactions. Recognizing these prospects, the researchers have founded a spin-out company called Disruptive Materials to commercialise and apply Upsalite.

More information: Forsgren J, Frykstrand S, Grandfield K, Mihranyan A, Strømme M (2013) A Template-Free, Ultra-Adsorbing, High Surface Area Carbonate Nanostructure. PLoS ONE 8(7): e68486. DOI: 10.1371/journal.pone.0068486

Abstract

We report the template-free, low-temperature synthesis of a stable, amorphous, and anhydrous magnesium carbonate nanostructure with pore sizes below 6 nm and a specific surface area of ~ 800 m2 g?1, substantially surpassing the surface area of all previously described alkali earth metal carbonates. The moisture sorption of the novel nanostructure is featured by a unique set of properties including an adsorption capacity ~50% larger than that of the hygroscopic zeolite-Y at low relative humidities and with the ability to retain more than 75% of the adsorbed water when the humidity is decreased from 95% to 5% at room temperature. These properties can be regenerated by heat treatment at temperatures below 100°C.The structure is foreseen to become useful in applications such as humidity control, as industrial adsorbents and filters, in drug delivery and catalysis.

Journal information: PLoS ONE

Source: The Conversation

This story is published courtesy of The Conversation (under Creative Commons-Attribution/No derivatives).