A versatile, clean and efficient way to enhance widespread application of carbon nanotubes

(PhysOrg.com) -- Researchers at Imperial College London have developed a versatile, practical and efficient method for activating sites on the surface of carbon nanotubes (CNTs) and subsequently binding a wide range of molecules to them. This new method will enable large-scale manufacture of modified CNTs.

The new method, reported this month in the journal Chemical Science, overcomes a major hurdle in the development of industrial scale applications for CNTs. It provides manufacturers with a method that, in principle, can be used to modify the surface chemistry of the underlying nanotube structure, on a large scale. Surface modification can provide new properties or enable subsequent processing steps: for example, molecules grafted to the CNTs may introduce catalytic activity or provide compatibility with particular solvents.

Our approach is potentially a very significant step towards manufacturing carbon nanotubes with specific chemical characteristics, so-called functionalisation, at an industrial scale," said Professor Milo Shaffer, lead author of the study from the Department Chemistry at Imperial College London. "Our method is extremely practical because, in principle, it can exploit existing infrastructure and yet it remains extremely versatile; the huge range of molecules that can be bound to the CNTs makes the technology adaptable to almost any application."

"Our technique is intrinsically scalable and, for the first time, it should be feasible to functionalise CNTs on the same scale as they are produced. This change is significant as industry's current capacity to manufacture CNTs is hundreds, if not thousands, of times greater than its capacity to add complex surface chemistry. This technique should increase the availability of functionalised CNTs, enable new applications that require manufacturing in bulk, and hence enhance the growth of the market," added Professor Shaffer.

The method that Professor Shaffer and his colleagues have developed should allow CNTs to be readily tailored to potential applications such as sensor networks, filters, electrodes for electrochemical devices, advanced catalysts and to improve CNT compatibility in, for example, composite materials, solvents, and electrolytes.

The key step in the new method involves activating CNTs at high temperatures under an inert atmosphere or vacuum. The high temperature treatment drives desorption of surface oxides on the CNT surface, producing reactive radicals that can subsequently bind a wide range of functional molecules to modify CNT physico-chemical properties. The radicals can also initiate the polymerisation of monomers, so that oligomers of functional molecules are bound to CNTs. The treatment does not cause any significant damage to the CNT structure, because the surface sites that it activates are already present on nanotubes manufactured using standard industrial methods. The number of reactive sites, and hence degree of functionalisation, can be increased by additional oxidation steps.

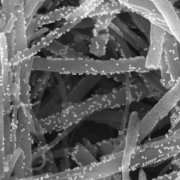

Professor Shaffer's team has demonstrated that the functional molecules are bound to, and uniformly distributed over, the surface of the CNTs. While the molecules are bound at relatively low densities, the degree of functionalisation is sufficient to offer benefits in industrial applications. The team has already demonstrated the attachment of catalytic metal particles, enhanced solubilities, and improved wetting with polymer matrices.

Professor Shaffer said: "The heat treatment to activate CNTs is compatible with some existing production technologies and can be easily adopted to work with others. Where the functional molecules to be added are volatile, the method can be carried out in the gas phase without the need for solvents, at any stage. The absence of solvent simplifies purification of the functionalised CNTs and, as many solvents used in wet-activation methods are corrosive and toxic, this option has environmental and hazard control benefits. It also has the advantage of being less damaging, less wasteful, and less time consuming than existing methods."

More information: A versatile, solvent-free methodology for the functionalisation of carbon nanotubes. Chemical Science 2010 DOI:10.1039/C0SC00287A

Provided by Imperial College London