Researchers develop world’s first blue-violet ultrafast pulsed semiconductor laser with 100 watt output

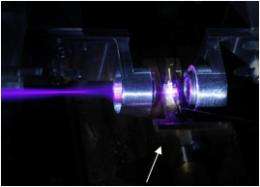

Tohoku University and Sony researchers have succeeded in developing a blue-violet ultrafast pulsed semiconductor laser with dramatically improved peak laser beam output levels that are 100 times that of the world's current highest levels.

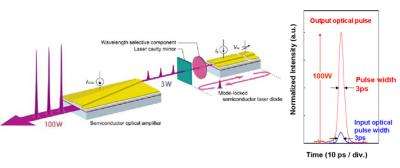

This latest successful development is an all-semiconductor laser picosecond pulse source with a laser wavelength of 405 nanometers in the blue-violet region. It is capable of generating optical pulses in the ultrafast duration of 3 picoseconds, with ultrahigh output peak power of 100 watts and repetition frequency of 1 gigahertz.

Advanced control of the newly-developed and proprietarily-constructed GaN-based mode-locked semiconductor laser and semiconductor optical amplifier have enabled peak output power in excess of 100 watts to be achieved, which is more than a hundred times the world’s highest output value for conventional blue-violet pulse semiconductor lasers.

Although there have been ultra high-output laser devices combining solid-state lasers and a second harmonic generation unit for high functionality and high-value leading-edge chemical research applications in the past, the light source box itself was bulky and a specialist technician was required to ensure the stable operation of the laser.

There are high expectations that this newly-developed semiconductor laser system, which incorporates semiconductor diodes, can have a much wider range of future applications. For instance, this technology enables the size of components such as the light source box to be drastically reduced.

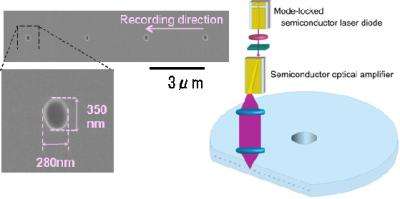

This newly-developed ultra high-output, ultrafast pulsed semiconductor laser light source is capable of using a nonlinear optical process known as two-photon absorption, which occurs only as a result of high intensity optical pulses. When light from the laser beam is concentrated on the lens, it creates chemical and thermal changes in the vicinity of the lens focus spot which is narrower than even the diameter of the focus spot of the lens itself.

It is anticipated that application of these properties will be possible in a wide range of fields such as three-dimensional (3D) nano-fabrication of inorganic/organic materials in the order of nanometers, and next-generation large-capacity optical disc storage.

Sony tested the principles for applying this technology in next-generation large-capacity optical disc-storage by creating void marks with a diameter of approximately 300 nanometers at intervals of 3 micrometers on the interior of plastic material, and successfully read these marks with the laser beam.

More information: These research findings were also published in the latest edition of Applied Physics Letters. (Appl. Phys. Lett. volume 97, issue 2, page 021101 (2010); doi:10.1063/1.3462942 (3 pages), Online Publication Date: 12 July 2010

Source: Sony