Peering into the never before seen (w/ Video)

(PhysOrg.com) -- Scientists can now peer into the inner workings of catalyst nanoparticles 3,000 times smaller than a human hair within nanoseconds. The findings point the way toward future work that could greatly improve catalyst efficiency in a variety of processes that are crucial to the world’s energy security, such as petroleum catalysis and catalyst-based nanomaterial growth for next-generation rechargeable batteries.

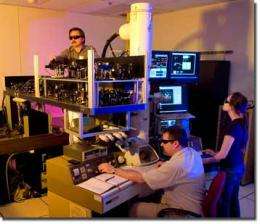

The work was performed in a collaborative effort by Lawrence Livermore National Laboratory and the University of California at Davis.

Using a new imaging technique on Lawrence Livermore’s Dynamic Transmission Electron Microscope (DTEM), researchers have achieved unprecedented spatial and temporal resolution in single-shot images of nanoparticulate catalysts.

The DTEM uses a laser-driven photocathode to produce short pulses of electrons capable of recording electron micrographs with 15-nanosecond exposure time. The recent addition of an annular dark field (ADF) aperture to the instrument has greatly improved its ability to time-resolve images of nanoparticles as small as 30 nanometers in diameter.

“Nanoparticles in this size range are of crucial importance to a wide variety of catalytic process of keen interest to energy and nanotechnology researchers,” said UC Davis’ Dan Masiel, formerly of LLNL and lead author of a paper appearing in the journal, ChemPhysChem. “Time-resolved imaging of such materials will allow for unprecedented insight into the dynamics of their behavior.”

Previously, particles smaller than 50 nanometers could not be resolved in the 15-nanosecond exposure because of the limited signal and low contrast without ADF aperature. But by using DTEM’s ADF, almost every 50-nanometer particle and many 30-nanometer ones became clearly visible because of the fast time resolution and high contrast.

“The stark difference between these two images clearly demonstrates the efficacy of annual dark field imaging when imaging samples with feature sizes near the resolution limit of DTEM,” Masiel said.

The new technique makes it easier to discern significant features when compared to bright field pulsed imaging. It allows for vastly improved contrast for smaller particles, widening the range of catalyst systems that can be studied using DTEM.

DTEM can record images with six orders of magnitude higher temporal resolution than conventional TEM and can provide important insights into processes such as phase transformations, chemical reactions and nanowire and nanotube growth.

Co-authors include LLNL’s Bryan Reed, Thomas LaGrange, Geoffrey Campbell, Ting Guo and Nigel Browning. The work was funded by the Department of Energy’s Office of Science, Office of Basic Energy Sciences, Materials Sciences and Engineering Division.

The article appears in the May 27 online edition of ChemPhys Chem.

Provided by Lawrence Livermore National Laboratory