Lasers, software and the Devil's Slide

Running for more than 1,000 kilometers along picturesque coastline, California's Highway 1 is easy prey for many of the natural hazards plaguing the region, including landslides.

The California Department of Transportation (Caltrans) is currently building a kilometer-long tunnel to bypass one of the most landslide-prone stretches of the highway, the Devil's Slide, to help ensure drivers' safe passage.

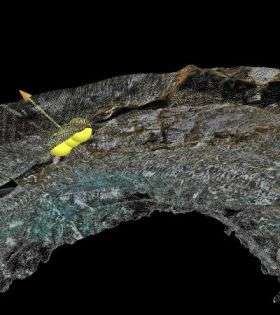

Using a new software package developed by researchers at Virginia Tech in Blacksburg, Va., project engineers are getting a detailed 3-D view of the rock exposed in the excavation, adding a new tool for improving both safety and construction progress.

Developed as part of a National Science Foundation Information Technology Research Initiative (ITR) project, the software, called "geotechnical Visualization Tool" (gVT), converts imagery of millions of rock-surface points--collected at a safe distance by a laser scanner--into an easily manipulated web of information. The data become a permanent digital record of the newly exposed material.

The scan data, at a resolution of 5 millimeters, provides information that the software program packages into enormous visualizations incorporating up to 10 meters of excavated tunnel. Engineers then use gVT to spot potential hazards to both the tunnel and the construction crews before weaknesses in the rock have a chance to trigger a collapse.

The information is so detailed that researchers can observe where rock layers are separating and how fractures are oriented. Researchers can even recreate sections of rock after they have fallen, providing a critical asset for determining where and how to safely drill. Because the data is portable, engineers can conduct all of the analyses from their home base at any time, far from the danger of the tunnel.

"Geologic maps have traditionally been made using manual measurements taken by geologists directly on the rock," said Joseph Dove, the lead developer of gVT at Virginia Tech and co-PI on the ITR project. "Laser scanning is revolutionary for underground mapping because it allows direct collection of digital data in three dimensions at high resolution."

After a careful analysis of the scanned data, the engineers can take manual follow-up measurements to confirm their results.

"These 3-D visualizations enhance geological documentation and an engineer's ability to make decisions," added Jeramy Decker, a Ph.D. graduate of Virginia Tech and co-developer of gVT, now at Kiewitt Pacific Company, the construction contractor excavating the tunnels.

In use as part of a suite of private industry engineering tools and software critical to the tunneling beneath Devil's Slide, gVT is the product of a two-year collaboration between civil engineers and computer scientists. The Devil's Slide application is the first use of gVT in a true construction environment.

Decker presented the new technique in a talk at the 42nd U.S.-Canada Rock Mechanics Symposium in San Francisco on June 29th.

Source: National Science Foundation