Cycling More Intelligently

Modern bicycles leave nothing to be desired. 21, 24, 27 gears! For many amateur cyclists, such luxury is too much of a good thing. They change gear too infrequently and too late, get out of breath and don’t enjoy the ride. At the Hannover Messe (April 21 through 25), Fraunhofer researchers are presenting a bicycle with an intelligent pedal crank that helps the biker to direct his strength into the pedals.

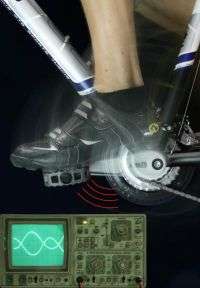

There are two piezo-sensors integrated in one of the pedal cranks of this bicycle. One function of the sensors is to measure the forces that propel the rider forwards and show him how ‘evenly’ he is pedaling. In the exhibited prototype, the registered data are transmitted wirelessly in real time to a PC – in practical use this would be a device such as a PDA or a cell phone.

The integrated-function pedal crank is a result of the InGuss project, whose goal is to manufacture ‘intelligent’ cast parts, by directly integrating sensors, actuators and electronic components in the parts while they are being cast. In this project, researchers at the Fraunhofer Institutes for Manufacturing Technology and Applied Materials Research IFAM, for Structural Durability and System Reliability LBF and for Integrated Circuits IIS are developing the manufacturing technology and the components to be integrated.

The special feature of the bicycle pedal crank is that the piezoceramic actuators, sensors and electronic components are integrated in the light metal components during casting. This is no easy task, for the high temperatures of over 700°C that prevail during casting can destroy the sensitive electronic and electromechanical components.

“We protect the components with special insulating materials, and adapt the process accordingly to prevent them from being damaged,” says Christoph Pille of the IFAM in Bremen. This would make it possible for the first time ever to integrate components such as RFID transponders during casting in such a way that they could not be lost, enabling components to be tracked, identified and protected against product piracy.

Heiko Atzrodt of the LBF is certain that this pedal crank demonstrator is just one example out of many potential applications for the technology: “Integrated sensor and adaptronic functions are likely to make their way into numerous products before long – for instance, sensors in aircraft parts could report material fatigue before it is too late. Integrated actuators make it possible to actively influence vibrations, too.”

Source: Fraunhofer-Gesellschaft