Researchers use high tech in mold watermark to protect plastic products from piracy

Researchers at WMG at the University of Warwick have devised a high tech way to add Anti-counterfeiting to plastic products as they are created in the moulding process. The process could cost less than one per cent of the total cost of manaufacturing the product.

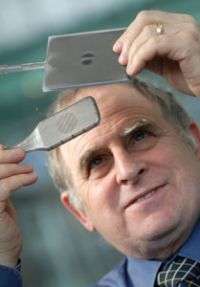

Lead researcher Professor Gordon Smith said:

"There is an enormous amount of interest in anti-counterfeiting technology for plastic products. We at the University of Warwick are working on several processes to prevent plastic components being copied and this 'in mould' process is the first of them to be developed for use."

"For commercial reasons we cannot detail collaborators but we are now exploring its use with one company that is plagued by the failure of a counterfeit plastic based safety critical product which is made to look exactly like their safety critical product and therefore damages their reputation as well as losing them sales."

The watermark is created as an intrinsic part of the plastic product as it is being moulded. It would require very detailed technical knowledge and equipment to even attempt to replicate the watermark process.

Professor Smith expects that the new technology will be of significant interest to a range of manufacturer’s products such as DVD s and other discs in the entertainment and computing markets to plastic containers used by a range of consumer industries.

Source: University of Warwick