Taking microelectronics to a new dimension

Metallic microstructures are the key components in almost every current or emerging technology. For example, with the next wireless communication standard (6G) being established, the need for advanced components and especially antennas is unmet. The drive to yet higher frequencies and deeper integration goes hand in hand with miniaturization and fabrication technologies with on-chip capability. Via direct laser writing—an additive manufacturing technology that offers sub-micron precision and feature sizes—highly sophisticated and integrated components come into reach.

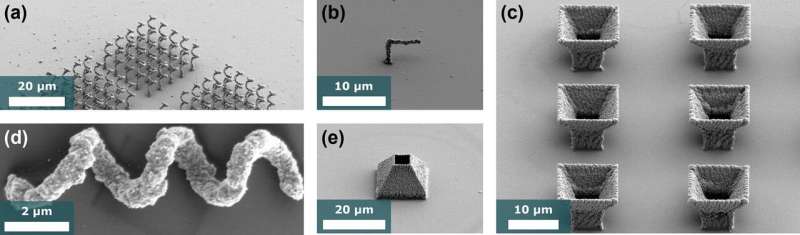

One major advantage of direct laser writing is that it is not limited to the fabrication of planar structures but enables almost arbitrary 3D microstructures. This dramatically increases the options available to component or device designers and offers vast potential for, e.g., antenna performance improvement: gain, efficiency and bandwidth are higher at lower feeding losses for 3D antennas compared to their planar counterparts. These advantages become even more pronounced the higher the frequency gets.

In a recent paper published in Light: Advanced Manufacturing, a team of scientists from the Fraunhofer ITWM, the Technische Universität Kaiserslautern and the Stuttgart University have developed a novel photosensitive material that enables direct fabrication of highly conductive microcomponents via direct laser writing.

"Not only are the resulting structures made of almost 100% silver, but they also have above 95% material density. Furthermore, almost arbitrary structure geometries are possible while onchip compatibility is maintained with this approach," says Erik Waller, the lead scientist of the project.

The feasibility and strength of the approach was demonstrated by the fabrication of a polarizer based on an array of helical antennas working in the infrared spectral region.

"The material and technology are well suited for the fabrication of conductive three dimensional micrometer-sized components. Next, we want to show the integration of thus fabricated components on conventionally fabricated chips. We then indeed take microelectronics to another dimension," says Georg von Freymann, head of department at the Fraunhofer ITWM and professor at the Technische Universität Kaiserslauten.

More information: Erik Hagen Waller et al, Photosensitive Material Enabling Direct Fabrication of Filigree 3D Silver Microstructures via Laser-Induced Photoreduction, Light: Advanced Manufacturing (2021). DOI: 10.37188/lam.2021.008

Provided by Chinese Academy of Sciences