Engineering students innovate 3-D printing process to improve accessibility

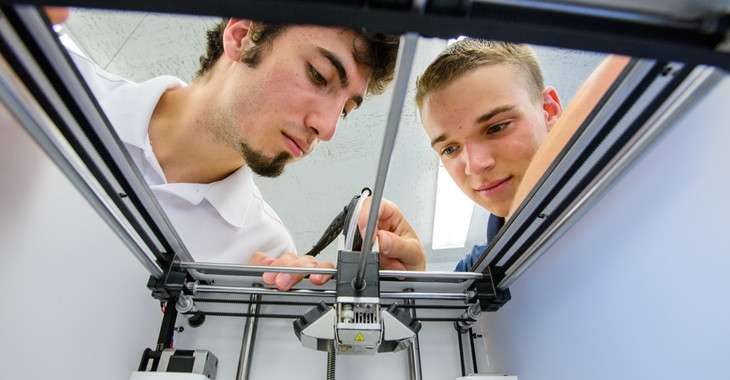

Penn State engineering students Kevin Paroda and Justin Keenan quickly discovered that they had much in common. As first-year roommates, they designed a keyless entry mechanism for their dorm room during the first week of school.

Paroda, pursuing biomedical engineering, and Keenan, electrical engineering and physics, found something else in common: They were both keenly interested in a 3-D printer in their engineering design class. And that was a problem. There were many other students also interested in using the printer.

"3-D printers can only build one model or print at a time," said Paroda. "And when it's finished, it needs to be removed before the next student can start their build.

"In lots of cases, the print sticks to the plate it's built on and has to be unstuck, which is time consuming and can potentially damage the print."

In their dorm room, Paroda and Keenan started considering ways to monitor the 3-D printer's progress from somewhere other than the lab and to control the process using software and Wi-Fi.

Talk turned into drawings, and drawings into the core conceptual idea the two presented at the College of Engineering Design Showcase. That's where they met Sven Bilen, a professor in Penn State's electrical engineering department and head of the School of Engineering Design, Technology and Professional Programs.

Bilen arranged for a grant from the College of Engineering to help Paroda and Keenan turn their idea into a working prototype.

"Initially, we were interested in creating software and a monitoring mechanism that enabled students to see the progress of a project online, as well as send digital drawings and place them in a queue," Keenan said.

"The more we got into it, we focused on the plate itself—developing one that prints don't stick to and that turns out multiple parts or units, one after another, without stopping."

In 2015, Paroda and Keenan's 3-D printer plate and software won the Lemelson-MIT "Use It" Undergraduate Team Award, for which they received $10,000.

At the College of Information Sciences and Technology Startup Week, President Eric J. Barron awarded Paroda and Keenan another $10,000 in funding—part of the Penn State Summer Founders Program, which enables new founders to learn from entrepreneurs and mentors and prepare for presentations to investors later in the year.

They have also received assistance from the New Leaf-Lion Launch Pad program. New Leaf is a community hub that collaborates with Penn State's Lion Launch Pad to provide entrepreneurs with time and space to develop their products, network with other entrepreneurs, and collaborate with interested community members.

Paroda and Keenan are also getting serious about commercializing their idea. With guidance from Bilen, the pair formed Mobium Solutions during their sophomore year. The company is attracting lots of attention.

"I took an entrepreneurial leadership course that focused on problem-based learning and communication and leadership skills," said Paroda. "That's been very helpful in understanding how we grow our company. Justin is focused on the technology, and I'm focused on the business."

Keenan adds: "Of all the 3-D printers in our country, our software and plate technology can successfully upgrade 70 percent—for roughly 10 percent of the cost of a new printer."

So what's next? The two are talking with companies across the country about the Mobium Solutions solution. And they are working with their professors to launch a Kickstarter campaign to take the young company to another level.

In addition, mechanical engineering junior Kyle Dolf has joined the Mobium team.

"Everybody at Penn State has been really helpful," said Paroda. "President Barron has been a huge supporter. We made him a 3-D printed bow tie for IST Startup Week, and he's been wearing it around campus."

If all works as planned, people around the country will be using Mobium Solutions' technology to make a lot more than bow ties.

Provided by Pennsylvania State University