February 20, 2015 feature

Pen draws flexible circuits using half-meter long carbon nanotube fibers

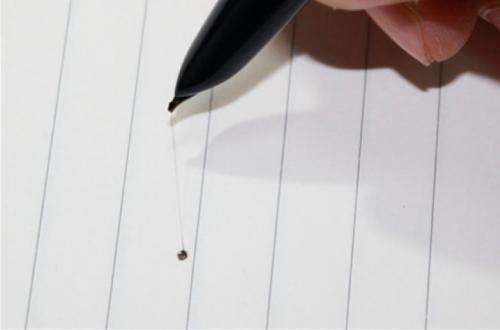

(Phys.org)—While it may look like researchers from Tsinghua University in Beijing are sketching out an idea for a circuit on a piece of paper, they're actually using a special pen that draws real circuits using carbon-nanotube-based ink.

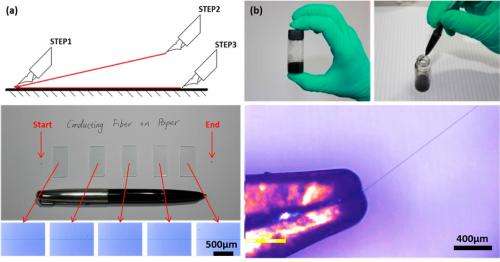

This technique, called "fiber drawing," has previously been used to construct patterns, but the fiber length is usually very short at just a few millimeters, and the drawing speed is typically very slow. These drawbacks limit its use in circuit fabrication.

In the new study, the researchers demonstrated that their new pen can draw carbon nanotube fibers that are more than a half of a meter long with fast drawing speeds of up to 10 cm/second. Their work is published in a recent issue of Nano Letters.

Due to the nanotube fibers' high conductivity and excellent mechanical flexibility, the researchers predict that the fibers could serve as the fundamental building blocks for a wide variety of flexible electronic devices, such as wearable electronics, flexible touch displays, flexible solar cells, RFIDs, and 3D devices.

While the pen itself is an ordinary commercial pen, the ink consists of a combination of electrically conductive carbon nanotube fibers and a viscous polymer solution called polyethylene oxide (PEO). The viscous PEO is highly elastic and mechanically strong, which allows it to pull long nanotube fibers from the solution during the writing process.

"The drawing technique allow us to achieve very long carbon nanotube fibers mainly due to the high molecular weight of the polymer and high viscosity of the precursor solution as ink," coauthor Hui Wu, Associate Professor at Tsinghua University, told Phys.org.

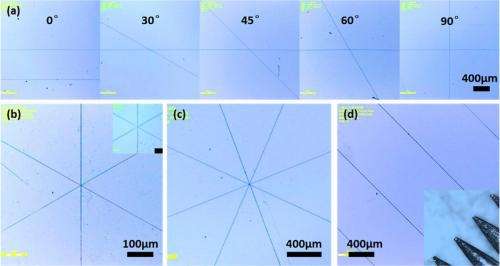

When writing, the pen is lifted off the paper to stretch and suspend the fibers, which can then be laid down on the substrate in the desired position. The researchers demonstrated that complex fiber patterns can be drawn by hand, and they predict that even greater precision can be achieved using advanced mechanical devices.

The researchers also showed that increasing the polymer concentration of the ink increases the diameter of the nanotube fibers from 300 nm to 3 µm. In general, thinner fibers have better conductivity than thicker ones due to their better fiber orientation.

Tests show that the highly conductive carbon nanotube fibers also exhibit excellent mechanical flexibility. At first, the researchers expected that the ultralong carbon nanotube fibers should maintain their conductivity after bending and distortion. Somewhat surprisingly, their tests showed that the fibers actually exhibit an increase in conductivity after bending—about a 30% increase after 1000 bending cycles. The researchers propose that the stress caused by bending deforms the polymers and improves nanotube alignment, which in turn increases conductivity.

In the future, the researchers hope to expand the drawing technique to use different types of ink for different purposes.

"We are now working on enabling more functions in the fiber," Wu said. "For example, one possibility is semiconducting fibers drawn from a pen tip for flexible device applications."

More information: Sihan Huang, et al. "Direct Writing of Half-Meter Long CNT Based Fiber for Flexible Electronics." Nano Letters. DOI: 10.1021/nl504150a

Journal information: Nano Letters

© 2015 Phys.org