New Argonne initiative to examine the details of the combustion process

Every science experiment and every mathematical model faces the same challenge: uncertainty.

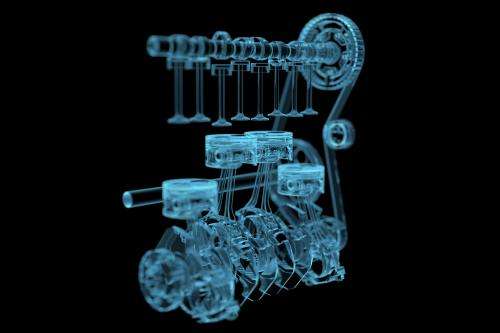

A complex system like an engine has many parameters that must be included in any reliable simulation. From fuel injectors to combustion chemistry, every part of the process of combustion has parameters with some level of uncertainty associated with them. These uncertainties are often extremely difficult for scientists to reduce. The field of uncertainty analysis provides the tools to investigate how parameter uncertainty influences simulation outcomes.

A team of researchers from the U.S. Department of Energy's Argonne National Laboratory is using a specific form of uncertainty analysis called global sensitivity analysis (GSA), which breaks down the uncertainty into constitute parts.

"There are lots of unknowns that are involved," said mechanical engineer Sibendu Som of the U.S. Department of Energy's (DOE) Argonne National Laboratory. "We're using sensitivity analysis to understand how they all affect overall uncertainty."

Researchers at Argonne, as part of the new Virtual Engine Research Institute and Fuels Initiative (VERIFI), are looking at a number of parameters in the internal combustion process. VERIFI is the first and only source in the world for high-fidelity, three-dimensional, end-to-end combustion engine simulation/visualization and simultaneous powertrain and fuel simulation, with uncertainty analysis.

The parameters being investigated include the relationships between the diameter of the nozzle in the fuel injector, the dynamics of the fuel spray, the proportion of fuel to air in the combustion chamber and the exhaust products. By gaining a better understanding of how these parameter uncertainties affect outcomes, the VERIFI researchers seek to create cleaner and more efficient engines.

Overall, Som and Argonne mechanical engineer Yuanjiang Pei and chemist Michael Davis have investigated 32 different parameters simultaneously, trying to establish how the uncertainties vary under different conditions. "If we can find a way to understand how uncertainty effects our simulations, we can take a step toward developing a more predictive simulation," Som said.

Building on several decades of work by chemists, statisticians, and applied mathematicians, Argonne chemists have developed the tools to apply GSA to large chemical models in collaboration with their colleagues at the University of Colorado and the University of Leeds.

These techniques were further refined in the last two years to allow their efficient application to engine simulations, leading to the present study, which involves a collaboration with the University of Connecticut. These new methods demonstrate the benefits of close collaboration between basic and applied research. "This is the first time we've applied these methods in such a complicated system," said Argonne mechanical engineer Doug Longman. "We have demonstrated that GSA can be used in a systematic way for something as complex as an engine simulation."

In particular, VERIFI researchers are taking an iterative approach in which data gathered from the simulations can be fed back to both engine modelers and combustion chemists to further reduce uncertainty and create more predictive engine simulations. "What's unique about VERIFI is the way we've refined the tools to create engine simulations that are more reliable and applied high-performance computing resources to run simulations faster and more intensively than ever before," Som said.

By taking advantage of the incredible computational power available today, the VERIFI team can identify the most important engine and fuel parameters and develop unique engine simulations and analyses to enable optimized engine combustion in the presence of uncertainty at any operating condition. In the near future, the VERIFI team plans to run diesel engine simulations of unprecedented scale on Mira, Argonne's 10-petaflop IBM Blue Gene/Q supercomputer.

Provided by Argonne National Laboratory