Engineers print a functioning 1.5m-wide prototype unmanned aerial vehicle

(Phys.org) —Engineers at the Advanced Manufacturing Research Centre (AMRC) at the University of Sheffield have successfully printed a 1.5m-wide prototype unmanned aerial vehicle (UAV) for a research project looking at 3D printing of complex designs.

The engineers said the polymer craft could form the basis of cheap and potentially disposable UAVs that could be built and deployed in remote situations potentially within as little as 24 hours.

Earlier versions required significant amounts of support material around component parts to prevent the airframe structures from deforming during the build process. Using support material adds a direct material cost, and significantly increases build time, in some cases by an order of magnitude. This is a result of the machine having to change between build and support structure heads after each printed layer.

New 3D printing techniques, such as the fused deposition modelling (FDM) used to make the UAV at Sheffield, could soon be used in the creation of products without the need for complex and expensive tooling and the time required in traditional manufacturing.

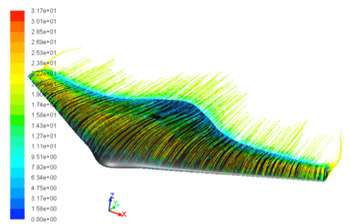

The UAV has already completed a test flight as a glider. Researchers are developing an electric ducted fan propulsion system that will be incorporated into the airframe's central spine. They plan to develop the craft for guidance by GPS or camera technology, controlled by an operator wearing first person-view goggles.

Dr Garth Nicholson who led the project said: "Following successful flight testing, we are working to incorporate blended winglets and twin ducted fan propulsion. We are also investigating full on-board data logging of flight parameters, autonomous operation by GPS, and control by surface morphing technology. Concepts for novel ducted fan designs are also being investigated".

The Sheffield UAV comprises nine parts that can be snapped together.

It weighs less than 2kg and is made from thermoplastic. The engineers are currently evaluating the potential of nylon as a printing material that would make the UAV 60 per cent stronger with no increase in weight.

Provided by University of Sheffield