Painting in virtual reality, no trial-and-error

Almost any product made of plastic, metal or wood is painted or coated. But colour doesn't come cheap. The biggest polluter in a factory is the painting and surface treatment processes. By painting in virtual reality you can find a cleaner way to do it. Advanced mathematical modelling is behind the breakthrough technology.

In an automotive factory, painting and surface treatment are the processes that consume most energy, water and chemicals and also produce most waste and pollution. If these processes can be improved, environmental savings are huge. Around 75 million cars are produced per year worldwide. Every drop of paint counts. Virtual tools are frequently used to support an effective product and production realization in other parts of the factory – but not in the painting section. A large number of prototypes are painted, washed and painted again, a slow and costly trial-and-error procedure.

As one of the first companies, Volvo Cars saw a great need to improve the painting preparation process. Future demands on fast adaption and tailored solutions for both new material combinations and new products, initiated a change. They turned to researchers at Fraunhofer-Chalmers Centre for help. AB Volvo, Scania CV, Swerea IVF and General Motors NA decided to join in and the virtual paint project was started.

Fredrik Edelvik is one of the members in the research group. As a mathematician with special interest in using numbers as a tool to improve industrial processes, he was happy to take on this assignment. "To us it posed great challenges for mathematical modelling and simulation. The combination of high physical complexity, large moving geometries, and demands on near real time results was stimulating."

No more wasted drops

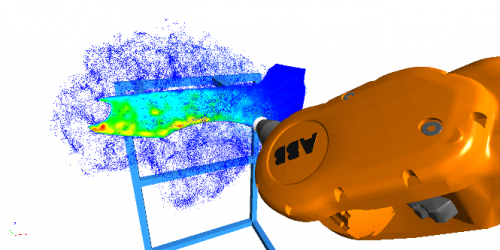

The challenge has ended up in a tool that handles all process trial steps virtually. With a virtual tool, the paint and surface treatment processes can be optimized to be more environmentally friendly, more energy and cost efficient, and give a better product quality. Fredrik explains why this tool is exceptional. "We have shown that it is possible to accurately simulate spray painting of a car in only a few hours on a standard computer. This is an extreme improvement compared to earlier approaches that required weeks of simulation time. Unique algorithms for coupled simulations of air flows, electrostatic fields and charged paint particles have made this possible."

These results give the possibility to systematically optimize current technology to reduce energy consumption, paint material, and cycle-time. Product quality is also improved by better coverage and less corrosion problems. Another positive effect is to support and facilitate a transfer from manual to automated surface treatment.

Hundreds of companies in Sweden are painting or coating thousands of products such as furniture, household appliances and windows. Many of them manually paint their products. The workers are then exposed to un-healthy paint substances. Harmful work tasks are safer performed by a robot. By offering software that can be used to shorten the lead time of programming a paint robot, more companies will be able to take the step from manual to robotized spray painting.

Moving from tests to spin-off

Fredrik is excited about the future. The results are so successful that a commercial continuation can be realised. "Volvo Cars has already implemented our virtual paint tool in their production. More will follow their lead. Therefore, we will investigate the potential to form a spin-off company during the coming year. We want to make this terrific tool available to as many as possible."

Tomorrow, Fredrik will continue his challenges as a researcher with projects about the brain and paperboard packages. Math is the path to many different journeys.

Provided by Chalmers University of Technology